SMT ịgbado ọkụ na-akpata

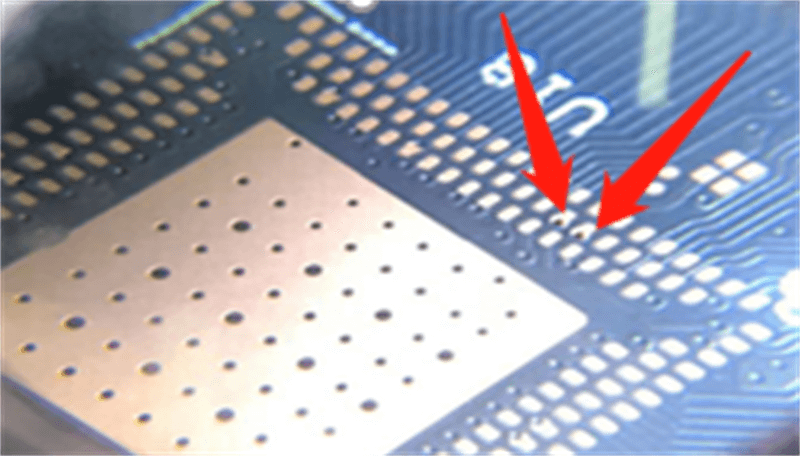

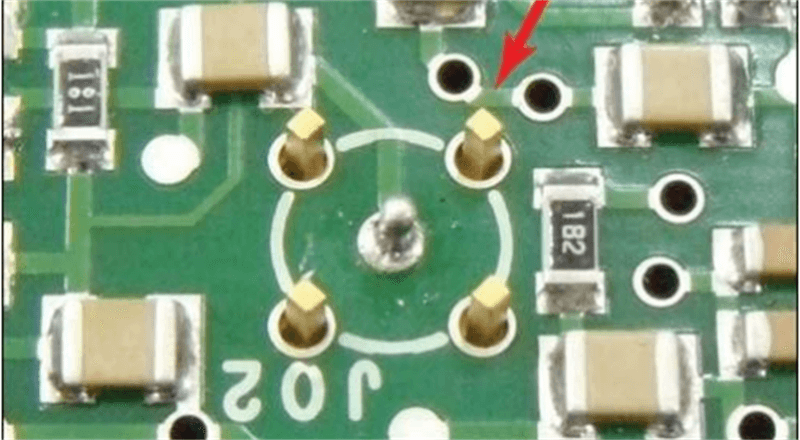

1. PCB mpe mpe akwa imewe ntụpọ

Na imewe usoro nke ụfọdụ PCB, n'ihi na ohere bụ dịtụ obere, oghere nwere ike na-egwuri na mpe mpe akwa, ma solder mado nwere fluidity, nke nwere ike banye n'ime oghere, n'ihi na enweghị solder mado na reflow ịgbado ọkụ, yabụ mgbe ntụtụ ezughi oke iri tin, ọ ga-eduga na ịgbado ọkụ.

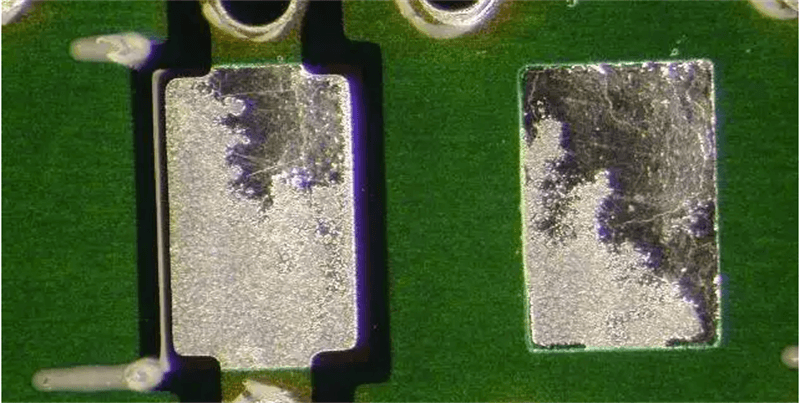

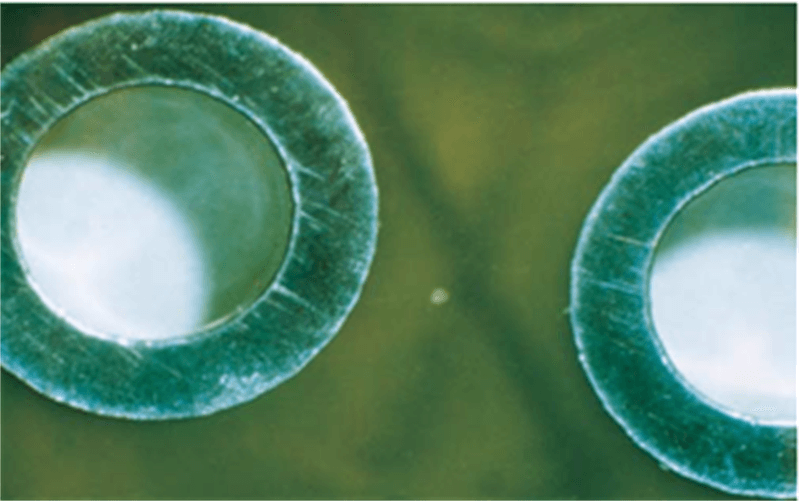

2.Pad elu oxidation

Mgbe emechara pad oxidized ahụ, ịgbado ọkụ ga-eduga na ịgbado ọkụ nke ọma, yabụ mgbe mpe mpe akwa oxidizes, ọ ga-ebu ụzọ kpoo ya.Ọ bụrụ na oxidation dị njọ, ọ dị mkpa ka ahapụ ya.

3.Reflow okpomọkụ ma ọ bụ elu okpomọkụ mpaghara oge ezughị

Mgbe emechara ihe nkedo ahụ, okpomọkụ anaghị ezuru mgbe ị na-agafe mpaghara reflow preheating na mpaghara okpomọkụ na-adị mgbe niile, na-eme ka ụfọdụ n'ime ọkụ na-agbaze agbaze nke na-emebeghị mgbe ịbanye na mpaghara reflow nke dị elu, na-akpata ezughị ezu tin iri nri. nke akụrụngwa pin, dapụtara na mebere ịgbado ọkụ.

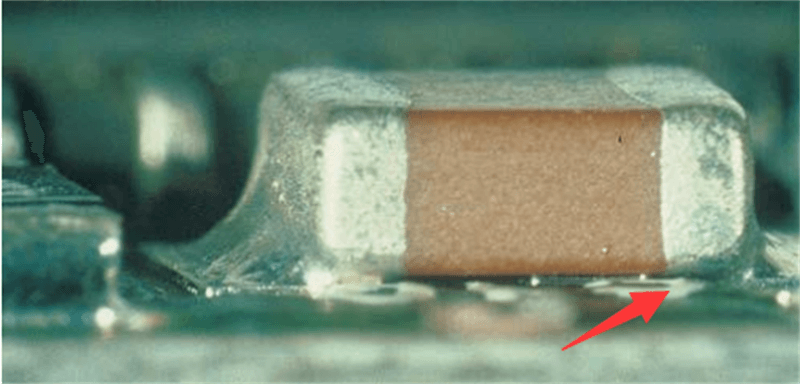

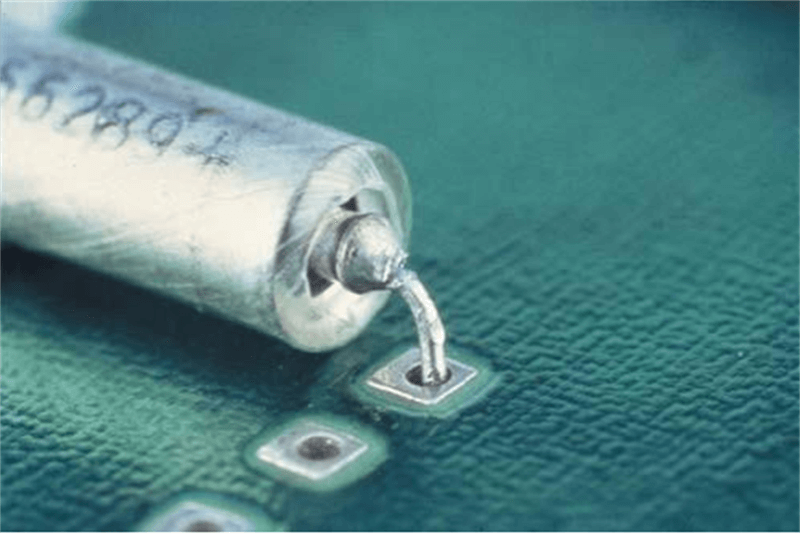

4.Solder mado obibi bụ obere

Mgbe solder tapawa na-brash, ọ nwere ike ịbụ n'ihi na obere oghere na ígwè ntupu na oké nrụgide nke na-ebi akwụkwọ scraper, n'ihi na obere solder mado obibi na ngwa ngwa volatilization nke solder mado maka reflow ịgbado ọkụ, dapụtara na mebere ịgbado ọkụ.

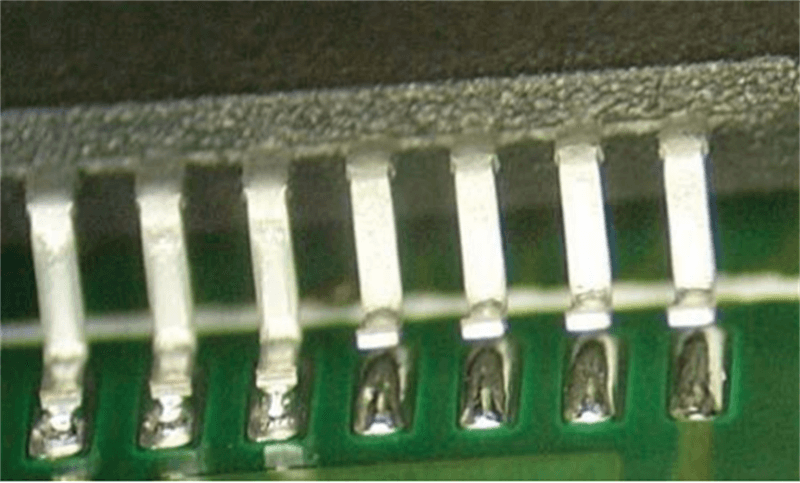

5.High-pin ngwaọrụ

Mgbe ngwaọrụ dị elu bụ SMT, ọ nwere ike ịbụ na n'ihi ihe ụfọdụ, akụkụ ahụ mebiri emebi, osisi PCB na-ehulata, ma ọ bụ nrụgide na-adịghị mma nke igwe ntinye ezughị ezu, na-eme ka agbaze dị iche iche na-ekpo ọkụ nke solder, na-akpata. mebere ịgbado ọkụ.

Ihe kpatara ịgbado ọkụ DIP mebere

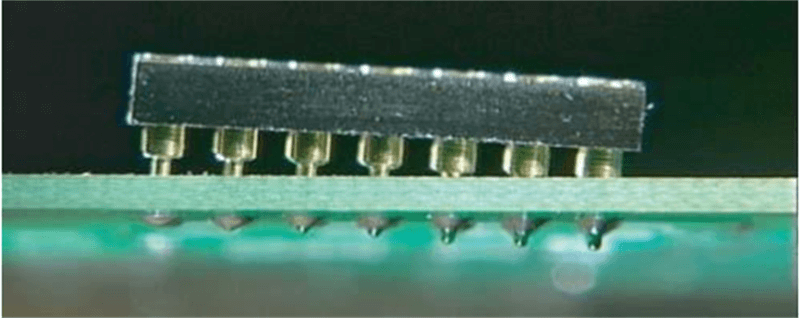

1.PCB nkwụnye nkwụnye oghere imewe ntụpọ

Oghere nkwụnye PCB, nnabata dị n'etiti ± 0.075mm, oghere nkwakọ ngwaahịa PCB buru ibu karịa pin nke ngwaọrụ anụ ahụ, ngwaọrụ ahụ ga-atọkwa ụtọ, na-akpata tin ezughị ezu, ịgbado ọkụ mebere ma ọ bụ ịgbado ọkụ ikuku na nsogbu ndị ọzọ dị mma.

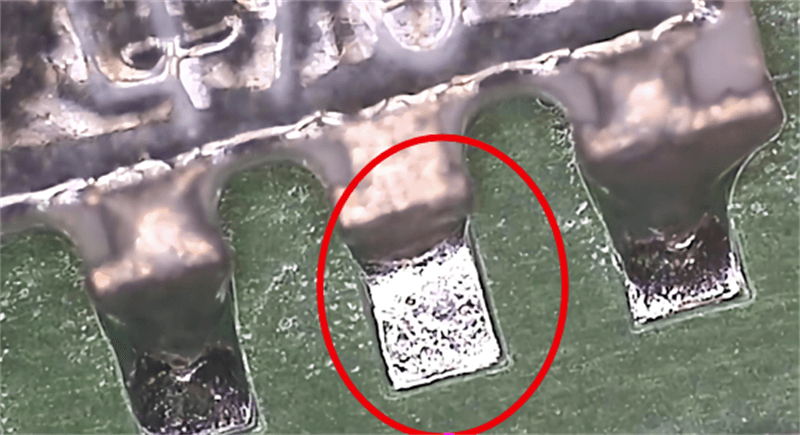

2.Pad na oghere oxidation

Oghere PCB na-adịghị ọcha, oxidized, ma ọ bụ metọọ ngwongwo zuru ezu, griiz, ọsụsọ, wdg, nke ga-eduga na weldability na-adịghị mma ma ọ bụ ọbụna na-abụghị weldability, na-ebute ịgbado ọkụ na ikuku ịgbado ọkụ.

3.PCB osisi na ngwaọrụ àgwà ihe

Bọọdụ PCB zụrụ azụ, akụrụngwa na ihe ndị ọzọ erughị eru, ọ nweghị nnwale nnabata siri ike emere, yana enwere nsogbu dị mma dị ka ịgbado ọkụ mebere n'oge mgbakọ.

4.PCB osisi na ngwaọrụ kubie ume

Bọọdụ PCB na ihe ndị a zụtara, n'ihi oge nchịkọta ọnụ ahịa dị ogologo, nke gburugburu ụlọ nkwakọba ihe na-emetụta, dị ka okpomọkụ, iru mmiri ma ọ bụ ikuku na-emebi emebi, na-ebute ihe ịgbado ọkụ dị ka ịgbado ọkụ mebere.

5.Wave soldering akụrụngwa ihe

The elu okpomọkụ na ife ịgbado ọkụ ọkụ na-eduga accelerated oxidation nke solder ihe na elu nke isi ihe, n'ihi na mbelata adhesion nke elu na mmiri mmiri solder ihe.Ọzọkwa, okpomọkụ dị elu na-emebikwa elu ihe na-adịghị mma nke ihe mgbakwasị ụkwụ, na-ebute mbelata ọrụ capillary na mgbasa ozi adịghị mma, na-ebute ịgbado ọkụ.

Oge nzipu: Jul-11-2023