SMT na-eji nyocha nke oghere ịgbado ọkụ nke ikuku reflow na-agbado ọkụ (2023 Essence Edition), ị kwesịrị ya!

1 Okwu mmalite

Na mgbakọ bọọdụ sekit, a na-ebipụta tapawa ihe na-ebu ụzọ na-ebipụta na bọọdụ sekit, mgbe ahụ, a na-etinye ihe elektrọn dị iche iche.N'ikpeazụ, mgbe reflow ọkụ, na tin beads na solder mado na-agbaze na ụdị nile nke electronic components na solder mpe mpe akwa nke sekit osisi na-welded ọnụ na-aghọta mgbakọ nke eletriki submodules.A na-eji teknụzụ elu elu (sMT) na ngwaahịa nkwakọ ngwaahịa dị elu, dị ka ngwugwu ọkwa sistemu (siP), ngwaọrụ ballgridarray (BGA), na ike iferi Chip, ngwugwu ewepụghị pin-less square (quad aatNo-lead, nke a na-akpọ QFN). ) ngwaọrụ.

N'ihi na e ji mara nke solder mado ịgbado ọkụ usoro na ihe, mgbe reflow ịgbado ọkụ nke ndị a nnukwu solder n'elu ngwaọrụ, a ga-enwe oghere na solder ịgbado ọkụ ebe, nke ga-emetụta eletriki Njirimara, thermal Njirimara na n'ibu Njirimara nke ngwaahịa Performance, na ọbụna na-eduga ngwaahịa ọdịda, ya mere, iji melite solder mado reflow ịgbado ọkụ oghere aghọwo a usoro na teknuzu nsogbu na a ga-edozi, ụfọdụ na-eme nnyocha enyochawo na-amụ ihe na-akpata nke BGA solder bọọlụ ịgbado ọkụ oghere, na nyere mmezi ngwọta, ot solder. Tapawa reflow usoro ịgbado ọkụ mpaghara nke QFN karịrị 10mm2 ma ọ bụ ịgbado ọkụ ebe karịrị 6 mm2 si iferi mgbawa ngwọta adịghị.

Jiri ịgbado ọkụ nke Preformsolder na oghere reflux ọkụ ịgbado ọkụ iji meziwanye oghere weld.Ihe ire ere emebere nke ọma chọrọ akụrụngwa pụrụ iche iji tụọ mgbanwe.Dịka ọmụmaatụ, a na-ewepụ mgbawa ahụ ma gbadaa nke ọma mgbe etinyere mgbawa ahụ ozugbo na ihe eji eme ihe.Ọ bụrụ na mgbawa mgbawa na-agbagharị agbagharị wee tụnye aka, usoro a na-abawanye site na ntugharị abụọ, na ọnụ ahịa nke ihe eji eme ihe na-eme ka ọ dị elu karịa mado solder.

Ngwá ọrụ reflux Vacuum dị ọnụ ala karị, ikike ikuku nke oghere oghere nke onwe ya dị oke ala, arụmọrụ ọnụ ahịa adịghị elu, na nsogbu ịgbasa tin dị njọ, nke bụ ihe dị mkpa na ntinye nke nnukwu njupụta na obere oghere. ngwaahịa.N'akwụkwọ a, dabere na usoro ịgbado ọkụ na-agbado agbado agbado agbado agbado agbado agbado, a na-emepụta usoro ịgbado ọkụ nke abụọ nke ọhụrụ wee webata iji kwalite oghere ịgbado ọkụ ma dozie nsogbu nke njikọta na mgbawa akara plastik kpatara site na oghere ịgbado ọkụ.

2 Solder mado obibi reflow ịgbado ọkụ oghere na mmepụta usoro

2.1 oghere ịgbado ọkụ

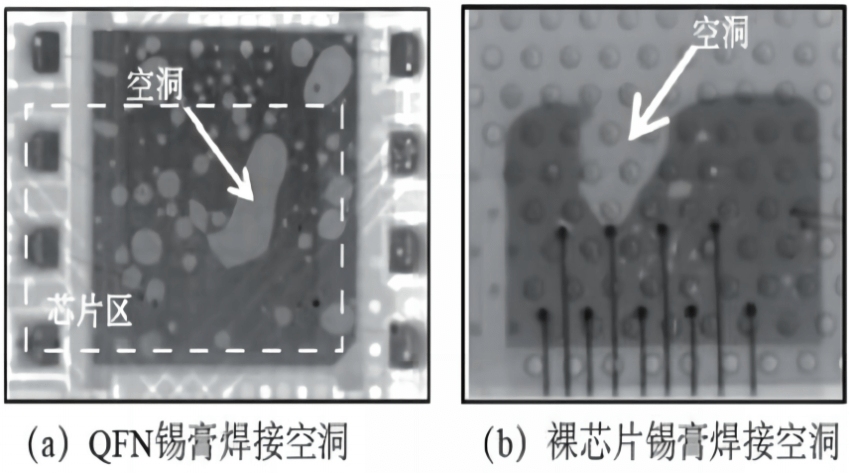

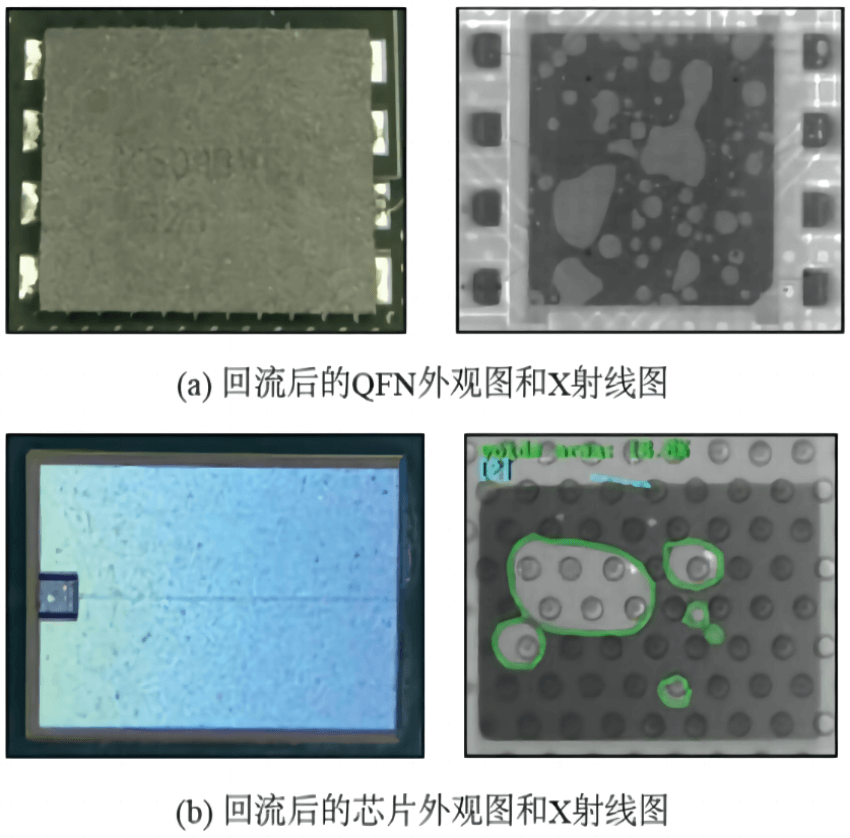

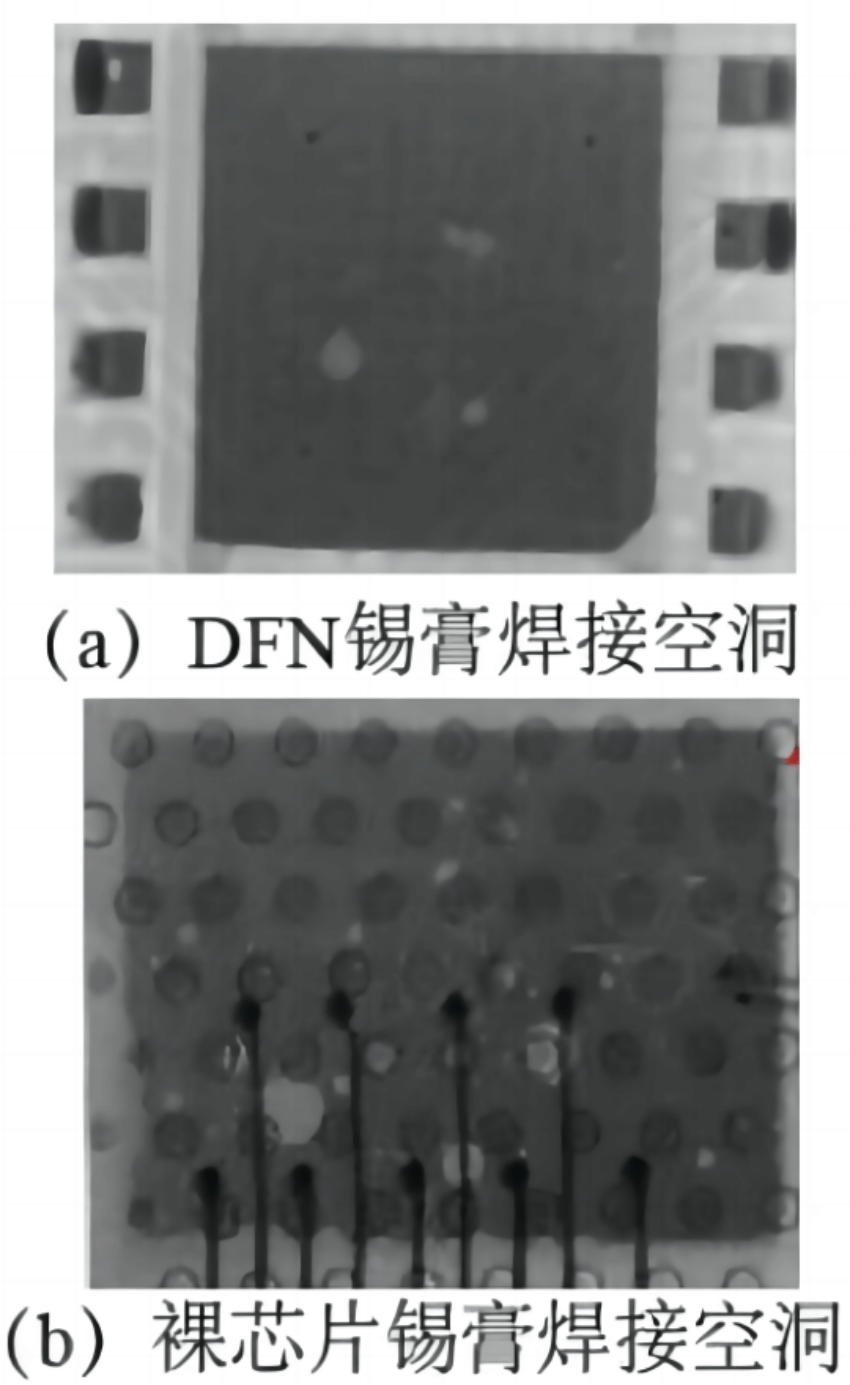

Mgbe ịgbado ọkụ gachara, a nwalere ngwaahịa a n'okpuru x-ray.Achọpụtara oghere ndị dị na mpaghara ịgbado ọkụ nwere agba dị ọkụ n'ihi enweghị ihe na-ere ya na oyi akwa ịgbado ọkụ, dị ka egosiri na foto 1.

Nchọpụta X-ray nke oghere afụ

2.2 Formation usoro nke ịgbado ọkụ oghere

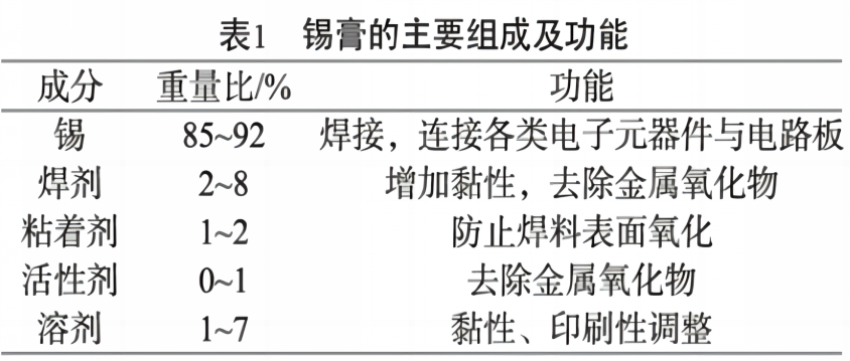

Na-ewere sAC305 solder tapawa dị ka ihe atụ, isi mejupụtara na ọrụ ka egosiri na Tebụl 1. The flux na tin beads jikọtara ọnụ na mado udi.Ogo ịdị arọ nke tin solder na flux bụ ihe dịka 9:1, na oke olu bụ ihe dịka 1:1.

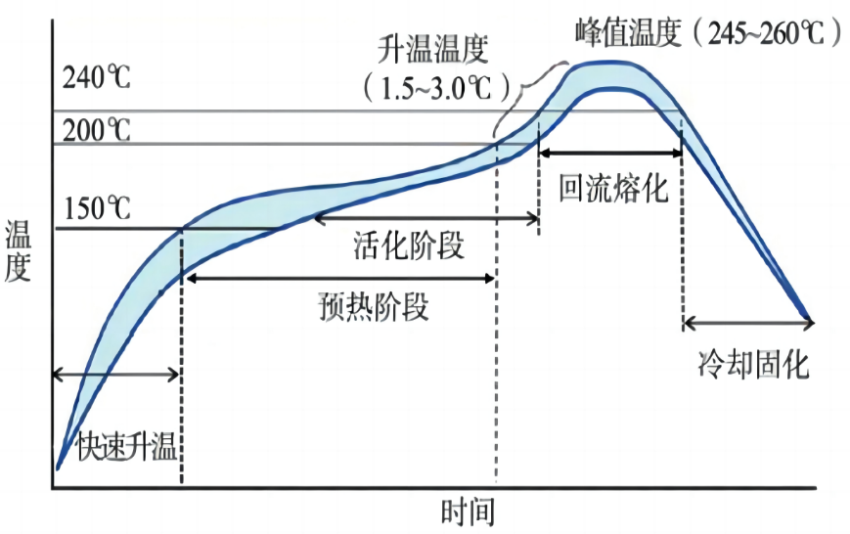

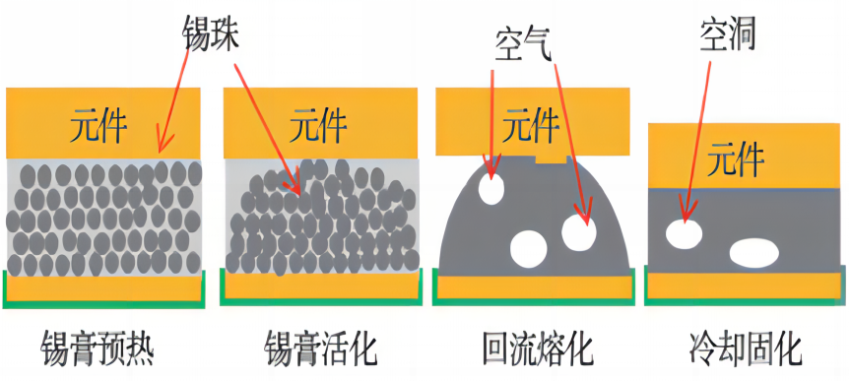

Mgbe e bipụtachara mado ya na ihe elektrọn dị iche iche, tapawa solder ga-enweta ọkwa anọ nke preheating, ịgbalite, reflux na jụrụ oyi mgbe ọ gafere n'ọkụ reflux.Ọnọdụ nke tapawa solder dịkwa iche na ọnọdụ okpomọkụ dị iche iche na ọkwa dị iche iche, dịka egosiri na foto 2.

Ntuziaka profaịlụ maka mpaghara ọ bụla nke reflow soldering

Na preheating na ịgbalite ogbo, ihe ndị na-agbanwe agbanwe na flux na solder mado ga-agbanwe na gas mgbe ọkụ.N'otu oge ahụ, a ga-emepụta gas mgbe a na-ewepụ oxide dị n'elu akwa akwa ịgbado ọkụ.Ụfọdụ n'ime ikuku ndị a ga-agbanwe wee hapụ tapawa ihe na-ere ahịa, a ga-ejikọta beads ndị na-ere ahịa nke ọma n'ihi ngbanwe nke mgbanwe.Na reflux ogbo, nke fọdụrụ flux na solder tapawa ga-ekupụ ngwa ngwa, tin beads ga-agbaze, a obere ego nke flux volatile gas na ọtụtụ n'ime ikuku n'etiti tin beads agaghị agbasasị n'oge, na ihe fọdụrụnụ na. tin gbazere na n'okpuru erughị ala nke gbazere agbaze bụ hamburger Sanwichi Ọdịdị na-ejide site sekit osisi solder pad na electronic components, na gas ọbọp na mmiri mmiri tin siri ike ịgbapụ naanị site elu buoyancy The elu agbaze oge dị nnọọ ukwuu. nkenke.Mgbe tin a wụrụ awụ jụrụ oyi wee ghọọ tin siri ike, pores na-apụta na oyi akwa nke ịgbado ọkụ, a na-emepụta oghere ndị na-ere ihe, dị ka egosiri na foto 3.

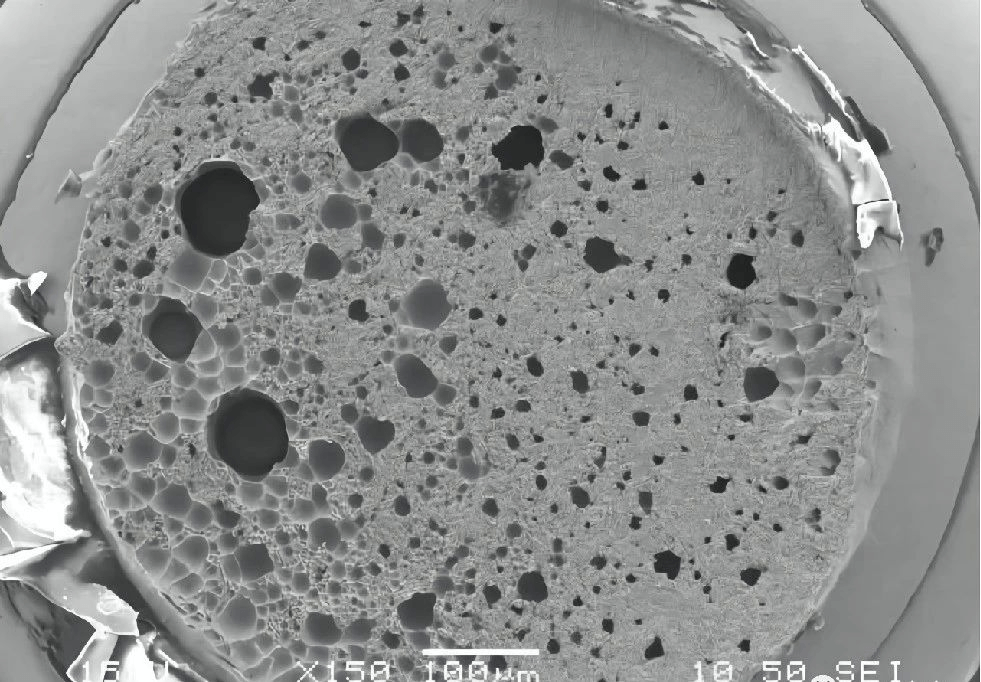

Eserese nke ihe efu emepụtara site na ịgbado ọkụ na-agbado mado reflow

Ihe na-akpata oghere ịgbado ọkụ bụ na ikuku ma ọ bụ gas na-agbanwe agbanwe nke a na-etinye na tapawa solder mgbe agbazechara anaghị apụcha kpamkpam.The mmetụta ihe na-agụnye solder mado ihe, solder mado obibi akwụkwọ udi, solder mado obibi ego, reflux okpomọkụ, reflux oge, ịgbado ọkụ size, Ọdịdị na na.

3. Nkwenye nke mmetụta ihe nke solder mado obibi reflow ịgbado ọkụ oghere

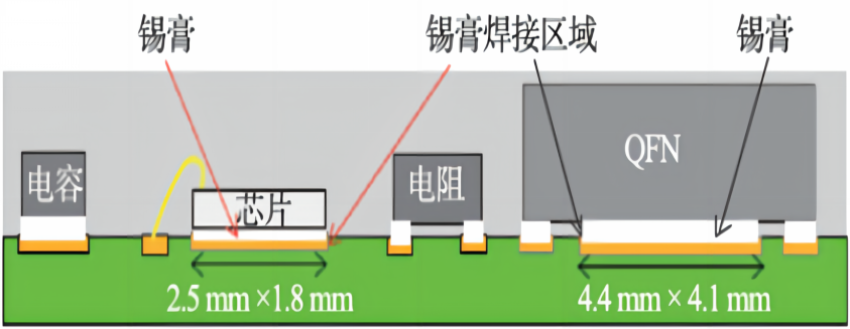

Eji QFN na ule mgbawa akwụghị ụgwọ iji kwado isi ihe na-ebute voids ịgbado ọkụ, yana ịchọta ụzọ a ga-esi melite oghere ịgbado ọkụ nkwụghachi site na tapawa solder ebipụtara.QFN na iferi mgbawa mado reflow welding ngwaahịa profaịlụ egosiri na Figure 4, QFN ịgbado ọkụ n'elu size bụ 4.4mmx4.1mm, ịgbado ọkụ n'elu bụ tinned oyi akwa (100% dị ọcha tin);Ogo ịgbado ọkụ nke mgbawa efu bụ 3.0mmx2.3mm, akwa akwa akwa akwa nickel-vanadium bimetallic na-agbado, na oyi akwa elu bụ vanadium.Mpempe akwụkwọ ịgbado ọkụ nke mkpụrụ ahụ bụ nickel-palladium ọla edo na-enweghị elektrọn, na ọkpụrụkpụ ya bụ 0.4μm/0.06μm/0.04μm.A na-eji tapawa SAC305 eme ihe, ihe eji ebi akwụkwọ bụ DEK Horizon APix, akụrụngwa ọkụ reflux bụ BTUPyramax150N, yana ngwa x-ray bụ DAGExD7500VR.

QFN na eserese ịgbado ọkụ na-enweghị ihe ọ bụla

Iji mee ka ntụnyere nsonaazụ ule dị mfe, a rụrụ ịgbado ọkụ n'okpuru ọnọdụ ndị dị na Tebụl 2.

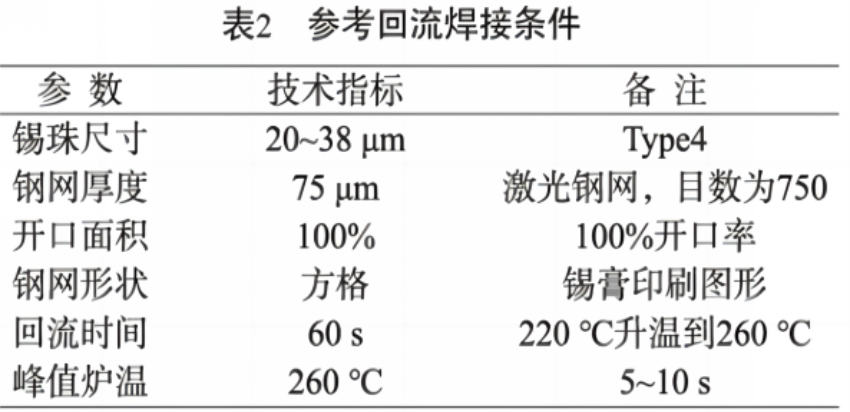

Tebụl ọnọdụ ịgbado ọkụ reflow

Ka emechara ịgbado elu na ịgbado ọkụ, X-ray hụrụ oyi akwa ahụ, wee chọpụta na enwere nnukwu oghere na oyi akwa ịgbado ọkụ na ala QFN na mgbawa efu, dị ka egosiri na eserese 5.

QFN na Chip Hologram (X-ray)

Ebe ọ bụ na tin bead size, nchara ntupu ọkpụrụkpụ, oghere mpaghara ọnụego, nchara ntupu udi, reflux oge na ọnụ ọgụgụ kasị elu ọkụ okpomọkụ ga-emetụta reflow ịgbado ọkụ voids, e nwere ọtụtụ mmetụta ihe, nke a ga-nyochaa ozugbo site DOE ule, na ọnụ ọgụgụ nke nnwale. otu ga-adị oke oke.Ọ dị mkpa iji ngwa ngwa nyochaa ma chọpụta isi ihe na-emetụta ya site na nyocha ntule njikọ, wee kwalitekwa isi ihe na-emetụta ya site na DOE.

3.1 Akụkụ nke oghere ndị na-ere ihe na akwa akwa akwa akwa akwa

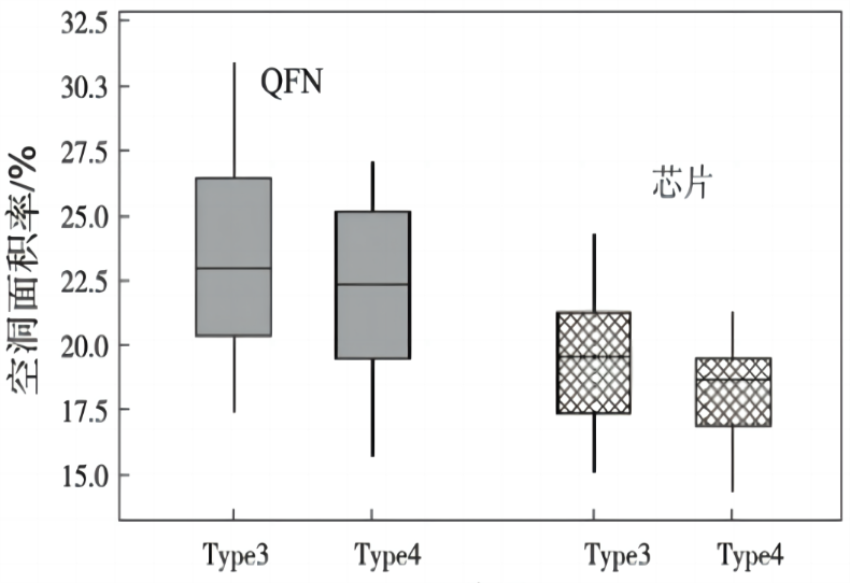

Na type3 (nha bead 25-45 μm) SAC305 solder tapawa ule, ọnọdụ ndị ọzọ na-agbanwe agbanwe.Mgbe ọ gbasasịrị, a na-atụ oghere ndị dị na akwa akwa akwa ma jiri ya na tapawa solder type4.A na-achọpụta na oghere ndị dị na akwa akwa akwa anaghị adị iche n'etiti ụdị abụọ nke tapawa nke solder, na-egosi na ihe nkedo nke nwere ụdị bead dị iche iche enweghị mmetụta doro anya na oghere ndị dị na oyi akwa, nke na-abụghị ihe na-emetụta ya. dị ka e gosiri na FIG.6 Dị ka egosiri.

Ntụle nke dara tin ntụ ntụ oghere nwere dị iche iche urughuru nha

3.2 Ọkpụrụkpụ nke oghere ịgbado ọkụ na nchara ígwè ebipụtara

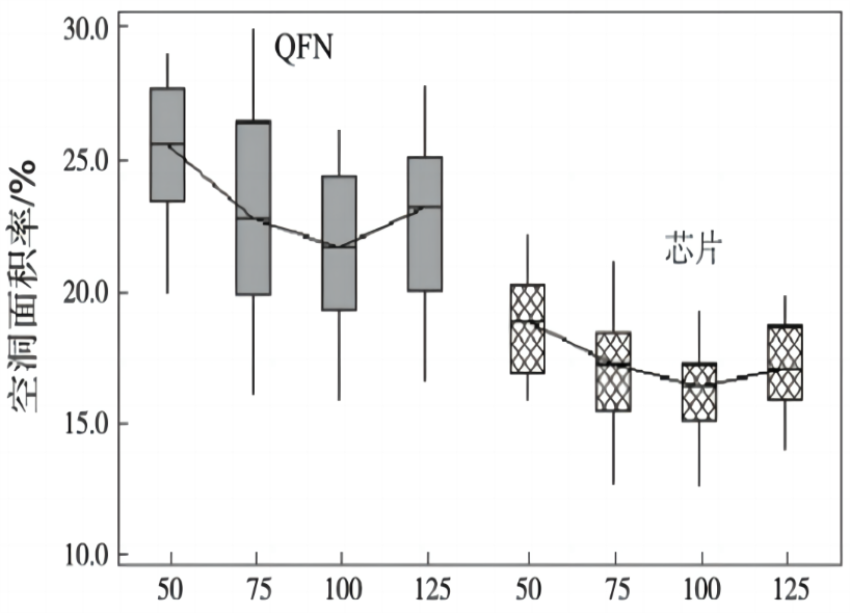

Mgbe ọ gbasasịrị, a tụrụ oghere oghere nke oyi akwa welded na nchara ígwè e biri ebi nke nwere ọkpụrụkpụ nke 50 μm, 100 μm na 125 μm, na ọnọdụ ndị ọzọ agbanwebeghị.Achọpụtara na mmetụta nke nha dị iche iche nke nchara nchara (nkwụsị) na QFN ka atụnyere nke nchara ígwè e biri ebi na ọkpụrụkpụ nke 75 μm Ka ọkpụrụkpụ nke nchara ígwè na-abawanye, oghere oghere na-eji nwayọọ nwayọọ na-ebelata.Mgbe ha ruru otu ọkpụrụkpụ (100μm), mpaghara oghere ahụ ga-atụgharị wee malite ịbawanye site na mmụba nke ọkpụrụkpụ nchara nchara, dị ka egosiri na eserese 7.

Nke a na-egosi na mgbe ego nke solder mado na-abawanye, mmiri mmiri tin na reflux na-kpuchie site mgbawa, na ntinye nke fọdụrụ ikuku mgbapụ bụ naanị warara na anọ n'akụkụ.Mgbe a na-agbanwe ego nke tapawa ihe na-ere ihe, a na-abawanye ụzọ mgbapụ ikuku fọdụrụnụ, na mgbawa ikuku nke etinyere na tin mmiri mmiri ma ọ bụ gas na-agbanahụ mmiri mmiri ga-eme ka tin mmiri na-efesa gburugburu QFN na mgbawa.

Nnwale ahụ chọpụtara na site n'ịbawanye ọkpụrụkpụ nke nchara nchara, afụ nke mgbapụ nke ikuku ma ọ bụ gas na-agbanwe agbanwe ga-abawanye, na ohere nke ịgbasa tin gburugburu QFN na mgbawa ga-abawanye n'otu aka ahụ.

Ntụnyere oghere na nchara nchara nke ọkpụrụkpụ dị iche iche

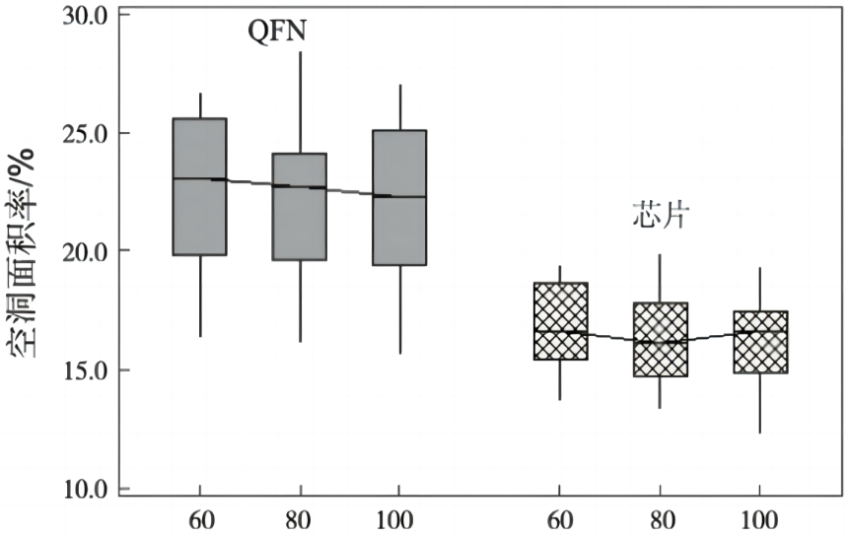

Mpaghara 3.3 nke oghere ịgbado ọkụ na oghere nchara nchara

A nwalere nchara ígwè e biri ebi nke nwere ọnụ ọgụgụ mmeghe nke 100%, 90% na 80%, na ọnọdụ ndị ọzọ agbanwebeghị.Mgbe ọ gbasasịrị, a tụrụ oghere oghere nke oyi akwa welded ma jiri ya tụnyere nchara ígwè e biri ebi na ọnụego mmeghe 100%.Achọpụtara na ọ nweghị nnukwu ọdịiche dị na oghere nke oyi akwa welded n'okpuru ọnọdụ nke ọnụ ọgụgụ mmeghe nke 100% na 90% 80%, dị ka egosiri na foto 8.

Ntụnyere oghere nke oghere oghere dị iche iche nke nchara ígwè dị iche iche

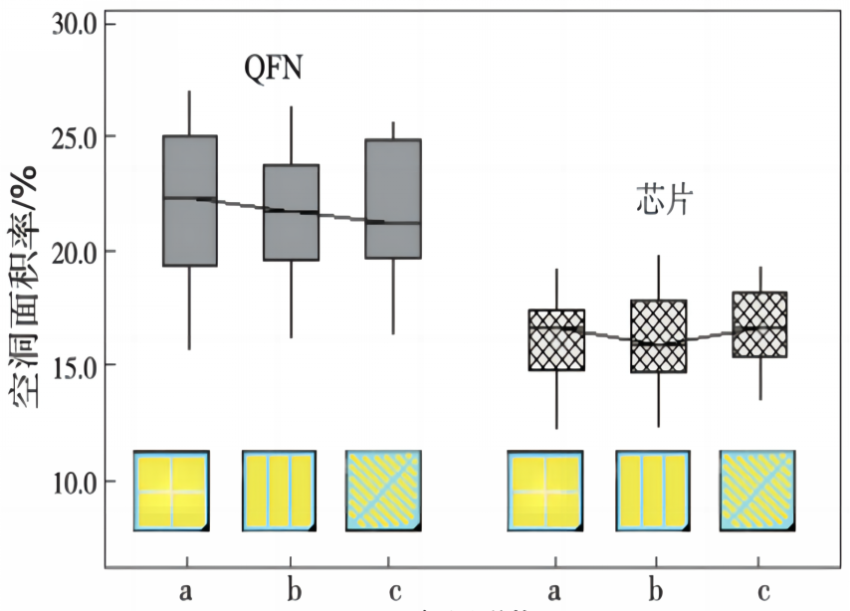

3.4 oghere welded na nchara nchara ebipụtara

Site na nnwale ụdị mbipụta nke tapawa nke warara nke warara b na grid nwere mmasị, ọnọdụ ndị ọzọ na-agbanwe agbanwe.Mgbe reflow, oghere oghere nke ịgbado ọkụ oyi akwa tụrụ na tụnyere na-ebi akwụkwọ udi nke okporo a.Achọpụtara na ọ nweghị nnukwu ọdịiche dị na oghere nke oyi akwa ịgbado ọkụ n'okpuru ọnọdụ grid, warara na grid nwere mmasị, dị ka egosiri na eserese 9.

Ntụle nke oghere dị iche iche ụdị oghere nke nchara nchara

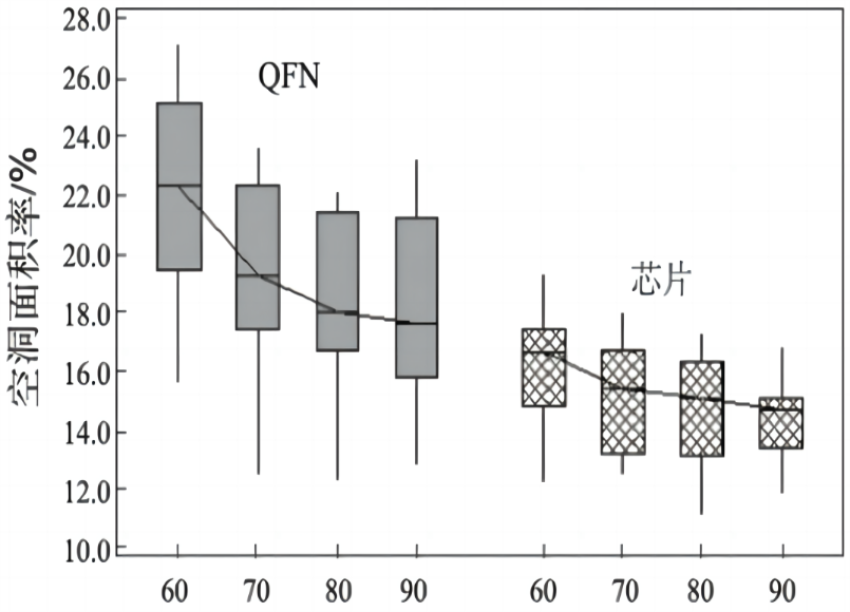

3.5 Welding oghere na oge reflux

Mgbe ogologo oge reflux (70 s, 80 s, 90 s) ule, ọnọdụ ndị ọzọ na-anọgide na-agbanweghi agbanwe, a tụrụ oghere na oyi akwa ịgbado ọkụ mgbe reflux, ma jiri ya tụnyere oge reflux nke 60 s, a chọpụtara na na mmụba nke oge reflux, ebe oghere ịgbado ọkụ na-ebelata, ma nbelata njupụta nke nta nke nta ji nwayọọ nwayọọ na-ebelata na mmụba nke oge, dị ka e gosiri na Figure 10. Nke a na-egosi na n'ihe banyere ezughị ezu reflux oge, ịba ụba oge reflux na-eme ka ikuku zuru oke. ọbọp na gbazere mmiri tin, ma mgbe reflux oge na-abawanye ruo oge ụfọdụ, ikuku ọbọp na mmiri mmiri tin na-esi ike toju ọzọ.Oge reflux bụ otu n'ime ihe na-emetụta oghere ịgbado ọkụ.

Ntụnyere efu nke ogologo oge reflux dị iche iche

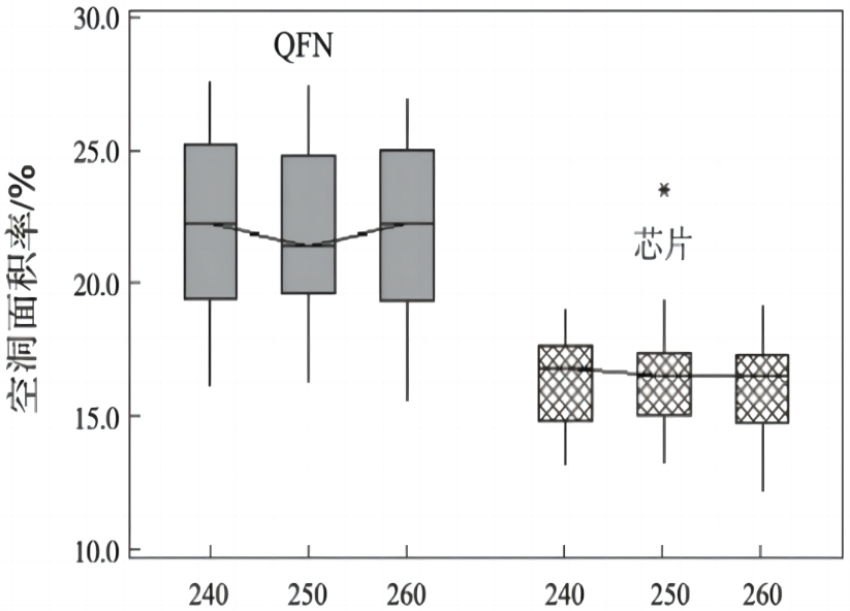

3.6 oghere ịgbado ọkụ na oke ọkụ ọkụ

Na 240 ℃ na 250 ℃ ọnụ ọgụgụ kasị elu ọkụ ule ule na ọnọdụ ndị ọzọ na-agbanweghi agbanwe, oghere ebe nke welded oyi akwa tụrụ mgbe reflow, na tụnyere 260 ℃ elu ọkụ okpomọkụ, ọ chọpụtara na n'okpuru dị iche iche elu ọkụ ọkụ ọnọdụ, oghere nke. welded oyi akwa nke QFN na mgbawa agbanwebeghị nke ukwuu, dị ka e gosiri na Figure 11. Ọ na-egosi na dị iche iche elu ọkụ okpomọkụ enweghị mmetụta doro anya na QFN na oghere na ịgbado ọkụ oyi akwa nke mgbawa, nke na-abụghị ihe na-emetụta.

Ntụnyere efu nke oke okpomọkụ dị iche iche

Nnwale ndị a dị n'elu na-egosi na ihe ndị dị mkpa na-emetụta oghere oyi akwa nke QFN na mgbawa bụ oge reflux na nchara nchara.

4 Solder mado ebipụta reflow ịgbado ọkụ oghere mma

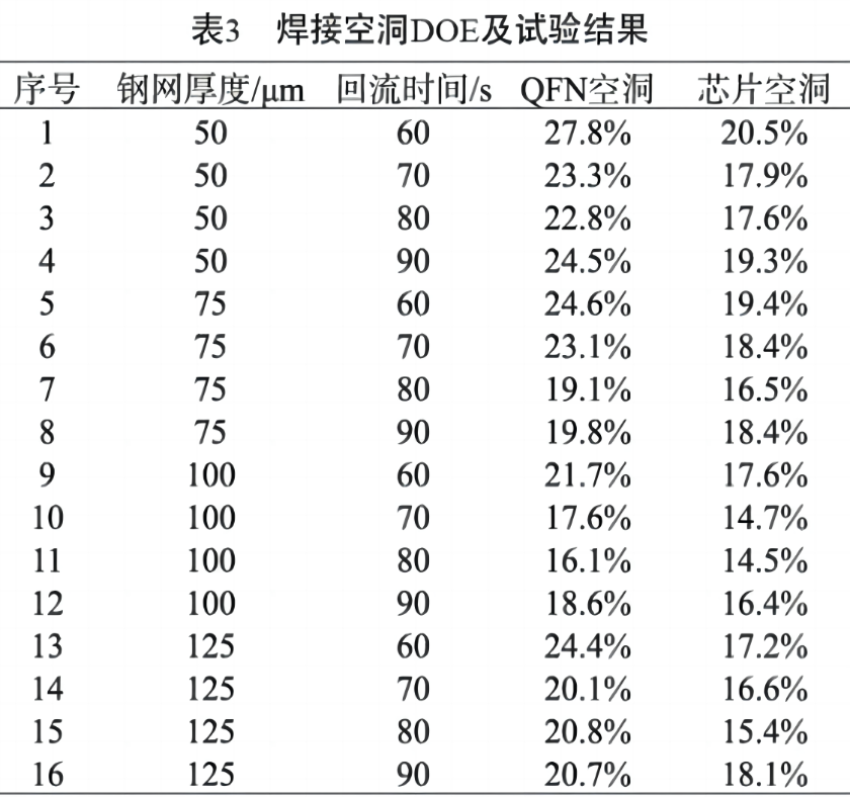

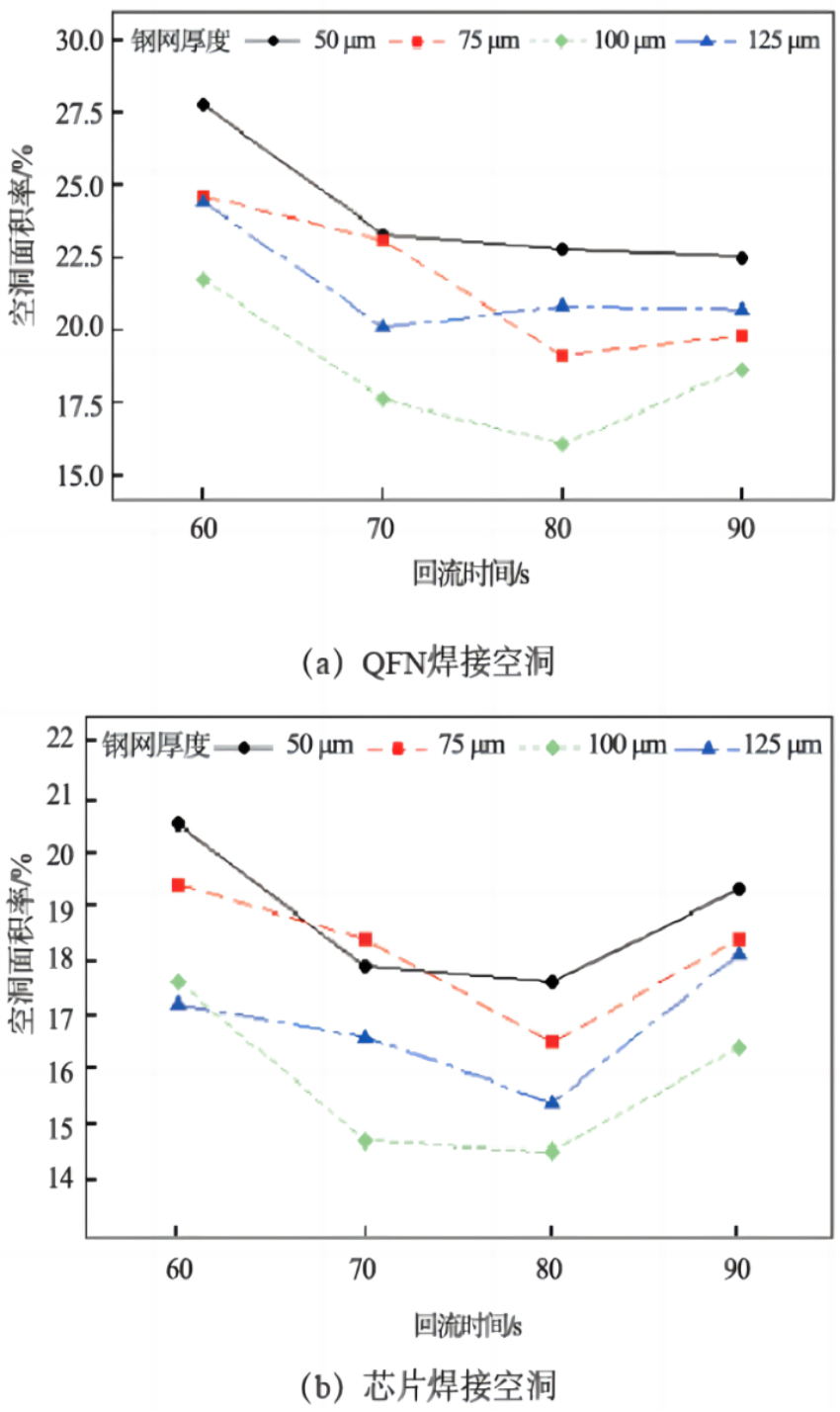

4.1 DOE ule iji meziwanye oghere ịgbado ọkụ

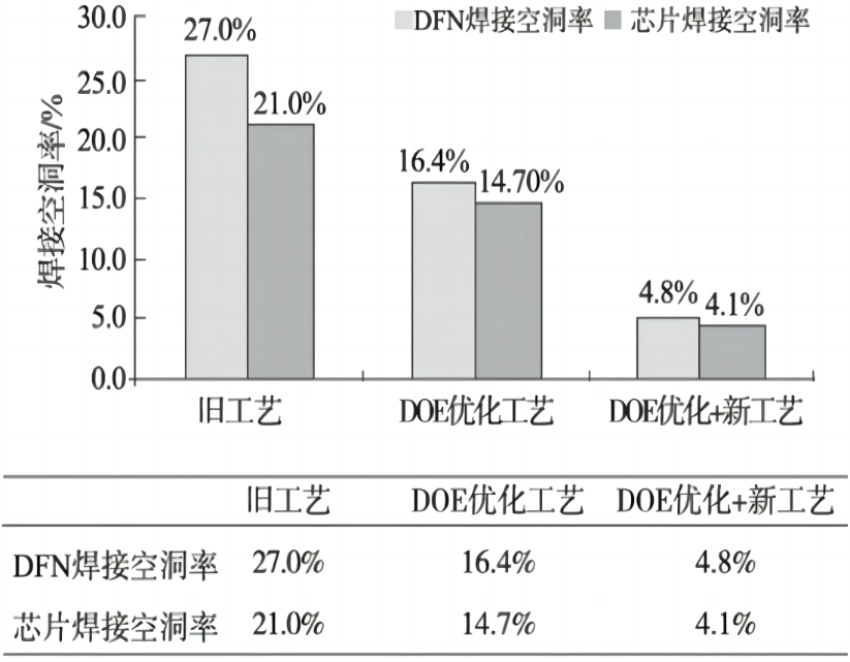

Emelitere oghere dị na akwa ịgbado ọkụ nke QFN na mgbawa site na ịchọta uru kacha mma nke isi ihe na-emetụta (oge reflux na nchara nchara).The solder mado bụ SAC305 type4, nchara ntupu udi bụ okporo ụdị (100% oghere ogo), ọnụnụ ọkụ okpomọkụ bụ 260 ℃, na ndị ọzọ ule ọnọdụ bụ otu ihe ahụ dị ka nke ule akụrụngwa.E gosipụtara ule DOE na nsonaazụ ya na Tebụl 3. Mmetụta nke nchara nchara nchara na oge reflux na QFN na oghere ịgbado ọkụ na-egosi na Figure 12. Site na nyocha mmekọrịta nke isi ihe na-emetụta, Achọpụtara na iji 100 μm ígwè ntupu ọkpụrụkpụ. na 80s reflux oge nwere ike ibelata oghere ịgbado ọkụ nke QFN na mgbawa.A na-ebelata ọnụego oghere ịgbado ọkụ nke QFN site na kacha 27.8% ruo 16.1%, yana ọnụego mgbawa nke mgbawa na-ebelata site na kacha 20.5% ruo 14.5%.

N'ime ule ahụ, emepụtara ngwaahịa 1000 n'okpuru ọnọdụ kachasị mma (100 μm nchara nchara nchara, oge reflux 80s), na ọnụego ịgbado ọkụ nke 100 QFN na mgbawa na-enweghị usoro.Nkezi oghere ịgbado ọkụ nke QFN bụ 16.4%, na nkezi ịgbado ọkụ oghere nke mgbawa bụ 14.7% O doro anya na ọnụ ọgụgụ weld oghere nke mgbawa na mgbawa na-ebelata.

4.2 Usoro ọhụrụ na-eme ka oghere ịgbado ọkụ dịkwuo mma

The n'ezie mmepụta ọnọdụ na ule na-egosi na mgbe ịgbado ọkụ oghere ebe na ala nke mgbawa bụ ihe na-erughị 10%, mgbawa oghere ọnọdụ cracking nsogbu agaghị eme n'oge ndu bonding na ịkpụzi.Usoro nke kachasị nke DOE enweghị ike izute ihe achọrọ maka nyocha na idozi oghere dị na ịgbado ọkụ na-agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado agbado.

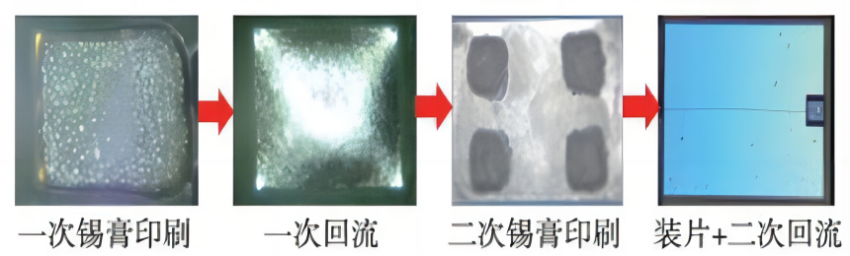

Ebe ọ bụ na mgbawa kpuchiri na ihe na-ere ahịa na-egbochi gas dị n'ime ihe na-ere ahịa ka ọ ghara ịpụ, ọnụ ọgụgụ oghere dị na ala nke mgbawa na-ebelata site n'iwepụ ma ọ bụ ibelata gas mkpuchi mkpuchi.A nakweere usoro ọhụrụ nke ịgbado ọkụ nke nwere mbipụta abụọ nke tapawa solder: otu mbipụta tapawa solder, otu reflow anaghị ekpuchi QFN na mgbawa efu na-ebunye gas na solder;E gosipụtara usoro a kapịrị ọnụ nke mbipụta akwụkwọ, patch na reflux nke abụọ na eserese 13.

Mgbe ebipụtara tapawa siri ike nke 75μm maka oge mbụ, ọtụtụ gas dị na solder na-enweghị mkpuchi mgbawa na-apụ n'elu, na ọkpụrụkpụ mgbe reflux dị ihe dị ka 50μm.Mgbe emechara nke mbụ reflux, a na-ebipụta obere oghere n'elu nke ihe na-eme ka ọ dị mma (iji belata ego nke tapawa, belata gas na-agbapụta, belata ma ọ bụ kpochapụ spatter), na tapawa ihe na-esi na ya. ọkpụrụkpụ nke 50 μm (nsonaazụ ule dị n'elu na-egosi na 100 μm kacha mma, ya mere ọkpụrụkpụ nke mbipụta nke abụọ bụ 100 μm.50 μm = 50 μm), wee tinye mgbawa ahụ, wee laghachi site na 80 s.Ọ fọrọ nke nta ka ọ bụrụ na ọ dịghị oghere na solder mgbe mbipụta mbụ na reflow, na solder mado na nke abụọ obibi dị obere, na welding oghere dị obere, dị ka e gosiri na Figure 14.

Mgbe abụọ mbipụta nke solder mado, oghere osise

4.3 nkwenye nke ịgbado ọkụ oghere mmetụta

Mmepụta nke ngwaahịa 2000 (ọkpụrụkpụ nke nchara nchara nke mbụ bụ 75 μm, ọkpụrụkpụ nke ntupu ígwè obibi akwụkwọ nke abụọ bụ 50 μm), ọnọdụ ndị ọzọ agbanweghị, nha nke 500 QFN na mgbawa ịgbado ọkụ, chọpụtara na usoro ọhụrụ ahụ. mgbe mbụ reflux ọ dịghị oghere, mgbe nke abụọ reflux QFN Oke ịgbado ọkụ oghere ọnụego bụ 4.8%, na kacha ịgbado ọkụ oghere ọnụego nke mgbawa bụ 4.1%.Tụnyere na mbụ otu-paste obibi akwụkwọ ịgbado ọkụ usoro na DOE kacha usoro, na ịgbado ọkụ oghere na-budata belata, dị ka e gosiri na Figure 15. Ọ dịghị mgbawa cracks hụrụ mgbe arụ ọrụ ule niile ngwaahịa.

5 Nchịkọta

The njikarịcha nke solder mado obibi ego na reflux oge nwere ike ibelata ịgbado ọkụ oghere ebe, ma ịgbado ọkụ oghere ọnụego ka buru ibu.Iji abụọ solder mado obibi reflow ịgbado ọkụ usoro nwere ike n'ụzọ dị irè na jirichaa na ịgbado ọkụ ọnụ ọgụgụ.Ebe ịgbado ọkụ nke QFN circuit iferi mgbawa nwere ike ịbụ 4.4mm x4.1mm na 3.0mm x2.3mm n'otu n'otu na uka mmepụta A na-achịkwa ọnụ ọgụgụ oghere nke ịgbado ọkụ n'okpuru 5%, nke na-eme ka mma na ntụkwasị obi nke ịgbado ọkụ.Nnyocha dị n'akwụkwọ a na-enye ntụaka dị mkpa maka imeziwanye nsogbu oghere ịgbado ọkụ nke nnukwu ebe ịgbado ọkụ n'elu.