Site na akụkọ mmepe nke mgbawa, ntụziaka mmepe nke mgbawa dị elu, nnukwu ugboro, obere ike oriri. Usoro imepụta mgbawa na-agụnyekarị imewe mgbawa, nrụpụta mgbawa, nrụpụta nkwakọ ngwaahịa, nnwale ọnụ na njikọ ndị ọzọ, n'ime nke usoro nrụpụta mgbawa dị mgbagwoju anya. Ka anyị leba anya na usoro nrụpụta mgbawa, ọkachasị usoro nrụpụta mgbawa.

Nke mbụ bụ mgbawa imewe, dị ka imewe chọrọ, “ụkpụrụ” emepụtara.

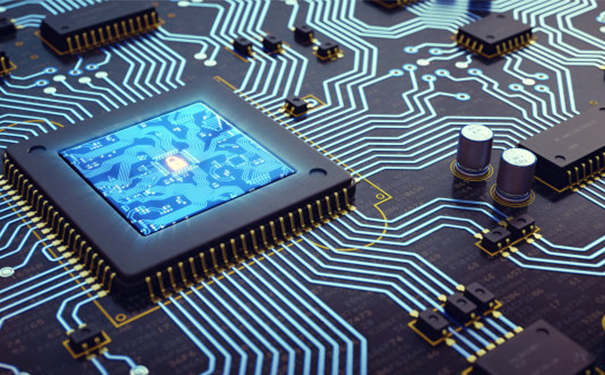

1, akụrụngwa nke mgbawa wafer

Ngwakọta nke wafer bụ silicon, a na-anụcha silicon site na ájá quartz, wafer bụ ihe na-eme ka ọ dị ọcha (99.999%), mgbe ahụ, a na-eme silicon dị ọcha ka ọ bụrụ mkpanaka silicon, nke na-aghọ quartz semiconductor ihe maka imepụta sekit agbakwunyere, iberi bụ mkpa kpọmkwem nke mgbawa mmepụta ihe. The thinner na wafer, ala na-eri nke mmepụta, ma elu usoro chọrọ.

2.Wafer mkpuchi

Ihe mkpuchi wafer nwere ike iguzogide oxidation na okpomọkụ, na ihe onwunwe bụ ụdị photoresistance.

3, wafer lithography mmepe, etching

Usoro a na-eji kemịkalụ na-emetụ ọkụ UV, nke na-eme ka ha dị nro. Enwere ike nweta ọdịdị nke mgbawa site na ịchịkwa ọnọdụ nke shading. A na-eji fotoresist kpuchiri wafer silicon ka ọ gbazee na ìhè ultraviolet. Nke a bụ ebe enwere ike itinye ndo mbụ, nke mere na akụkụ nke ìhè UV na-agbaze, nke nwere ike ịsacha ya na ihe mgbaze. Ya mere, ndị ọzọ n'ime ya bụ otu ọdịdị dị ka ndò, nke bụ ihe anyị chọrọ. Nke a na-enye anyị oyi akwa silica anyị chọrọ.

4, Tinye ihe adịghị ọcha

A na-akụnye ion n'ime wafer iji mepụta semiconductor P na N kwekọrọ.

Usoro a na-amalite site na ebe a na-ekpughere na wafer silicon ma tinye ya na ngwakọta nke ion kemịkal. Usoro a ga-agbanwe ka mpaghara dopant si eduzi ọkụ eletrik, na-enye ohere ka transistor ọ bụla gbanye, gbanyụọ ma ọ bụ buru data. Mpempe ibe dị mfe nwere ike iji naanị otu oyi akwa, mana ibe dị mgbagwoju anya na-enwekarị ọtụtụ ọkwa, a na-emeghachi usoro ahụ ugboro ugboro, nke dị iche iche jikọtara site na windo mepere emepe. Nke a yiri mmepụta ụkpụrụ nke oyi akwa PCB osisi. Iberibe dị mgbagwoju anya nwere ike ịchọ ọtụtụ akwa silica, nke enwere ike nweta site na lithography ugboro ugboro na usoro dị n'elu, na-eme nhazi akụkụ atọ.

5.Wafer ule

Mgbe usoro dị iche iche nke dị n'elu gasịrị, wafer ahụ guzobere lattice nke ọka. A na-enyocha njirimara eletrik nke ọka ọ bụla site na 'ntụgharị agịga'. N'ozuzu, ọnụ ọgụgụ nke ọka nke ọ bụla mgbawa bụ nnukwu, na ọ bụ a nnọọ mgbagwoju usoro ịhazi a pin test mode, nke na-achọ uka mmepụta nke ụdị na otu mgbawa nkọwa dị ka o kwere mee n'oge mmepụta. Ọnụ ọgụgụ dị elu, ọnụ ahịa ọnụ ahịa dị ala, nke bụ otu n'ime ihe mere ngwaọrụ mgbawa isi ji dị ọnụ ala.

6. Encapsulation

Mgbe emechara wafer, a na-edozi pin, a na-emepụta ụdị nkwakọ ngwaahịa dị iche iche dịka ihe achọrọ. Nke a bụ ihe mere otu mgbawa isi nwere ike inwe ụdị nkwakọ ngwaahịa dị iche iche. Dịka ọmụmaatụ: DIP, QFP, PLCC, QFN, wdg. Nke a na-ekpebi nke a site n'omume ngwa nke ndị ọrụ, gburugburu ngwa ngwa, ụdị ahịa na ihe ndị ọzọ dị n'akụkụ.

7. Nnwale na nkwakọ ngwaahịa

Mgbe usoro ahụ dị n'elu, emechala nrụpụta mgbawa, nzọụkwụ a bụ ịnwale mgbawa, wepụ ngwaahịa ndị na-adịghị mma, na nkwakọ ngwaahịa.

Ihe dị n'elu bụ ọdịnaya metụtara ya nke usoro nrụpụta mgbawa nke Mepụta Core Detection haziri. Enwere m olileanya na ọ ga-enyere gị aka. Companylọ ọrụ anyị nwere ndị injinia ọkachamara na ndị otu ọkachamara ụlọ ọrụ, nwere ụlọ nyocha 3 ahaziri ahazi, mpaghara ụlọ nyocha ahụ karịrị mita 1800, nwere ike ịme nyocha nyocha nke akụrụngwa elektrọnik, njirimara IC eziokwu ma ọ bụ ụgha, nhọrọ imewe ngwaahịa, nyocha ọdịda, nyocha ọrụ, nyocha ihe akụrụngwa na-abata na teepu na ọrụ nnwale ndị ọzọ.

Oge nzipu: Jun-12-2023