Usoro mmepụta PCBA zuru ezu (gụnyere usoro DIP dum), bata ma hụ!

"Usoro ire ere"

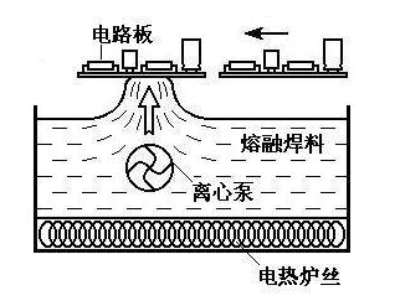

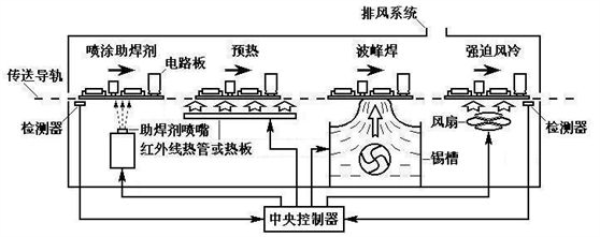

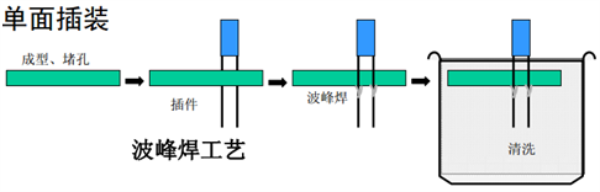

Ịsacha ebili mmiri bụ usoro ịgbado ọkụ maka ngwaọrụ nkwụnye. Ọ bụ a usoro nke a wụrụ awụ solder mmiri, site n'enyemaka nke mgbapụta, na-etolite a kpọmkwem udi nke solder ife na mmiri mmiri elu nke solder tank, na PCB nke etinyere akụrụngwa na-agafe solder ife elu na a kpọmkwem akụkụ na a ụfọdụ immersion omimi na nnyefe yinye iji nweta solder nkwonkwo ịgbado ọkụ, dị ka e gosiri na ọnụ ọgụgụ n'okpuru.

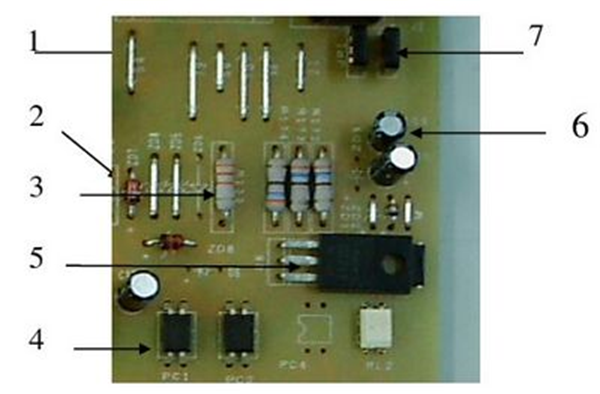

Usoro usoro n'ozuzu ya bụ nke a: ntinye ngwaọrụ --PCB loading --elling soldering --PCB mbupu --DIP pin trimming -- nhicha, dị ka egosiri na foto dị n'okpuru.

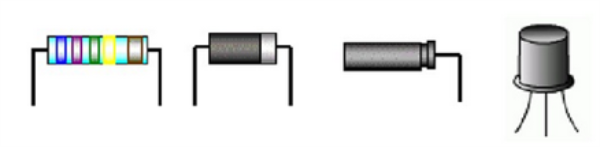

Teknụzụ ntinye 1.THC

1. Ngwakọta pin akpụ

Ngwa DIP kwesịrị ịkpụzi tupu itinye ya

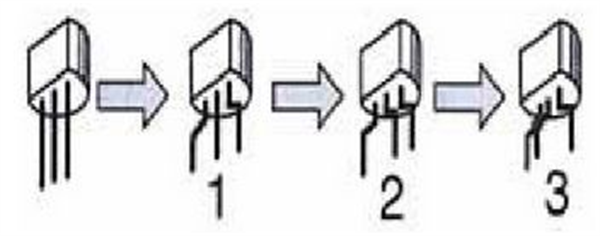

(1) Nhazi akụrụngwa ejiri aka mee: Enwere ike iji tweezers ma ọ bụ obere screwdriver kpụzie pin, dị ka egosiri na foto dị n'okpuru.

(2) The igwe nhazi nke components na-akpụzi: a na-eji igwe na-emepụta ihe pụrụ iche arụ ọrụ nke igwe na-emepụta ihe, ụkpụrụ ya bụ na feeder na-eji nri vibration na-eri nri ihe, (dị ka plug-in transistor) na nkesa iji chọta transistor, nzọụkwụ mbụ bụ na-ehulata atụdo n'akụkụ abụọ nke ekpe na n'akụkụ aka nri; Nzọụkwụ nke abụọ bụ ịgbada ntụtụ etiti azụ ma ọ bụ tụgharịa ka ọ mepụta. Dị ka e gosiri na foto na-esonụ.

2. Fanye akụrụngwa

Site na teknụzụ ntinye oghere na-ekewa n'ime ntinye aka na ntinye akụrụngwa akpaka

(1) Ntinye akwụkwọ ntuziaka na ịgbado ọkụ kwesịrị ibu ụzọ tinye ihe ndị ahụ achọrọ ka a rụzie ya n'ụzọ igwe, dị ka igwe jụrụ oyi, bracket, clip, wdg, nke ngwaọrụ ike, wee tinye ihe ndị achọrọ ịgbado na idozi. Emetụkwala ntụtụ akụrụngwa na foil ọla kọpa dị na efere obibi akwụkwọ ozugbo mgbe ị na-etinye ya.

(2) nkwụnye ihe nrụnye akpaaka (nke a na-akpọ AI) bụ teknụzụ mmepụta akpaaka kachasị elu na ntinye nke ngwaahịa eletrọnịkị nke oge a. Ntinye nke akụrụngwa akpaaka kwesịrị ibu ụzọ tinye ihe ndị ahụ nwere ịdị elu dị ala, wee wụnye ihe ndị ahụ nwere ịdị elu dị elu. Ekwesịrị itinye akụrụngwa isi bara uru na ntinye ikpeazụ. Echichi nke ikpo ọkụ ọkụ, bracket, clip, wdg kwesịrị ịdị nso na usoro ịgbado ọkụ. E gosipụtara usoro mgbakọ nke ihe PCB na ọnụ ọgụgụ ndị a.

3. Ịzụ ahịa ife

(1) Ụkpụrụ na-arụ ọrụ nke ire ere

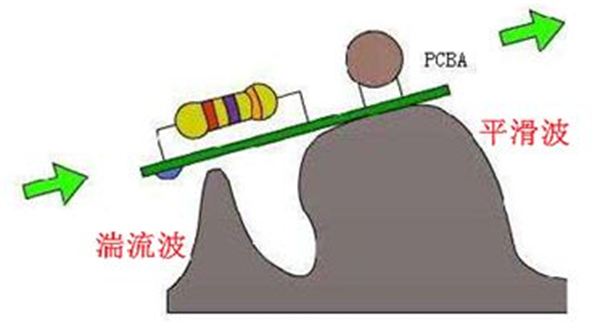

Ịzụ ahịa Wave bụ ụdị nkà na ụzụ nke na-etolite otu ụdị nke ebili mmiri na-agbapụta n'elu mmiri mmiri a wụrụ awụ site na nrụgide mgbapụta, ma na-etolite ebe a na-ere ihe na pin ịgbado ọkụ mgbe akụkụ mgbakọ na-etinye ya na ihe ahụ na-agafe na ebili mmiri na-agbapụta n'akụkụ akụkụ. The akụrụngwa na mbụ preheated na ịgbado ọkụ igwe preheating mpaghara n'oge usoro nke nnyefe site yinye ebu (mkpụrụ preheating na okpomọkụ ga-enweta ka na-achịkwa predetermined okpomọkụ usoro). Na ịgbado ọkụ n'ezie, ọ na-adịkarị mkpa ijikwa okpomọkụ dị ọkụ nke elu akụkụ ahụ, ya mere ọtụtụ ngwaọrụ agbakwunyela ngwaọrụ nchọpụta ọnọdụ okpomọkụ kwekọrọ (dịka nchọpụta infrared). Mgbe preheating, nzukọ na-abanye n'ime ụzọ uzo maka ịgbado ọkụ. Tank tank ahụ nwere sọda mmiri a wụrụ awụ, na nozzle dị na ala nke igwe nchara na-efesa ebili mmiri nwere ụdị nke ihe a wụrụ awụ, nke mere na mgbe elu ịgbado ọkụ nke ihe ahụ na-agafe na ebili mmiri ahụ, ebili mmiri na-ekpo ọkụ na-ekpo ọkụ, na ebili mmiri na-agbadokwa mpaghara ịgbado ọkụ ma gbasaa iji mejupụta, n'ikpeazụ nweta usoro ịgbado ọkụ. E gosipụtara ụkpụrụ ọrụ ya na foto dị n'okpuru.

Ịzụ ahịa ebili mmiri na-eji ụkpụrụ nnyefe okpomọkụ convection na-ekpo ọkụ ebe ịgbado ọkụ. The wụrụ awụ solder ife omume dị ka okpomọkụ isi iyi, n'otu aka na-eru na-asa pin ịgbado ọkụ ebe, n'aka nke ọzọ na-arụkwa a okpomọkụ conduction ọrụ, na pin ịgbado ọkụ ebe na-ekpo ọkụ n'okpuru a edinam. Iji hụ na ebe ịgbado ọkụ na-ekpo ọkụ, ọkụ na-ere ọkụ na-enwekarị obosara ụfọdụ, nke mere na mgbe ihu igwe nke akụkụ ahụ na-agafe na ebili mmiri ahụ, enwere ikpo ọkụ zuru oke, wetting, na ihe ndị ọzọ. N'ịsere ebili mmiri ọdịnala, a na-ejikarị otu ebili mmiri eme ihe, ebili mmiri ahụ dịkwa larịị. Site n'iji ihe na-ere ụzọ, a na-anabata ya ugbu a n'ụdị ifegharị abụọ. Dị ka e gosiri na foto na-esonụ.

Ntụtụ nke akụrụngwa na-enye ụzọ maka onye na-ere ahịa iji mikpuo n'ime metallized site na oghere na steeti siri ike. Mgbe ntụtụ metụrụ ebili mmiri na-ere ere, ihe na-ere mmiri mmiri na-arịgo ntụtụ na mgbidi oghere site na esemokwu elu. Omume capillary nke agbazere site na oghere na-eme ka ịrị elu nke ihe na-ere ihe na-eme ka ọ dị mma. Mgbe onye na-ere ahịa rutere na pad PcB, ọ na-agbasa n'okpuru ọrụ nke esemokwu elu nke pad ahụ. Ihe na-ere ahịa na-arị elu na-ekpochapụ gas na ikuku site na oghere ahụ, si otú ahụ na-ejuputa oghere ahụ ma na-akpụ nkwonkwo solder mgbe ọ dị jụụ.

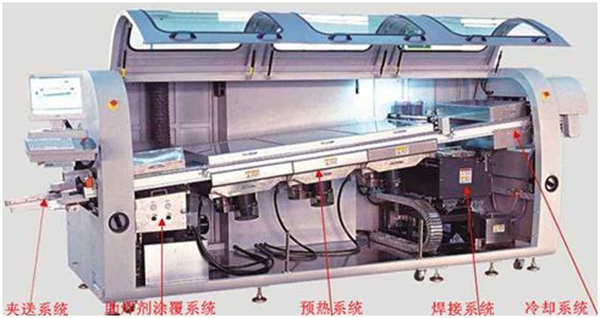

(2) Ihe ndị bụ isi nke igwe ịgbado ọkụ na ebili mmiri

Igwe ịgbado ọkụ nke ebili mmiri bụ nke nwere eriri ebufe, igwe na-ekpo ọkụ, tankị gbamgbam, mgbapụta, na ngwaọrụ na-agbapụta ụfụfụ (ma ọ bụ ịgbasa). A na-ekewa ya na mpaghara ịgbakwụnye, mpaghara preheating, mpaghara ịgbado ọkụ na mpaghara jụrụ oyi, dị ka egosiri na foto a.

3. Main iche n'etiti ife soldering na reflow ịgbado ọkụ

Isi ihe dị iche n'etiti ebili mmiri ịgbado ọkụ na reflow ịgbado ọkụ bụ na kpo oku isi iyi na solder ọkọnọ usoro na ịgbado ọkụ dị iche iche. N'ebe a na-ere mmiri, a na-ekpo ọkụ na-ekpo ọkụ ma na-agbaze ya na tank, na ebili mmiri na-emepụta site na mgbapụta na-arụ ọrụ abụọ nke isi okpomọkụ na ihe na-ere ahịa. Ebili mmiri a wụrụ awụ na-ekpo ọkụ site na oghere, pads, na ntụtụ akụrụngwa nke PCB, ebe ọ na-enyekwa ihe na-ere ihe dị mkpa iji mepụta nkwonkwo solder. Na reflow soldering, solder (solder mado) na-ebu ụzọ ekenye ya na ebe ịgbado ọkụ nke PCB, na ọrụ nke okpomọkụ isi iyi n'oge reflow bụ re-agbaze ọzọ solder.

(1) 3 Okwu mmalite nke usoro ire ere nke ebili mmiri

Wave soldering akụrụngwa e mepụtakwara ihe karịrị 50 afọ, na nwere uru nke elu mmepụta arụmọrụ na nnukwu mmepụta na n'ichepụta nke site-oghere components na sekit mbadamba, n'ihi ya, ọ bụ otu ugboro kasị mkpa ịgbado ọkụ akụrụngwa na akpaka uka mmepụta nke electronic ngwaahịa. Agbanyeghị, enwere oke na ngwa ya: (1) paramita ịgbado ọkụ dị iche.

Dị iche iche solder nkwonkwo na otu sekit osisi nwere ike ịchọ nnọọ iche ịgbado ọkụ parameters n'ihi na ha dị iche iche e ji mara (dị ka okpomọkụ ike, pin spacing, tin penetration chọrọ, wdg). Otú ọ dị, e ji mara nke ife soldering bụ iji mezue ịgbado ọkụ nke niile solder nkwonkwo na dum circuit osisi n'okpuru otu set parameters, otú dị iche iche solder nkwonkwo mkpa "dozie" ọ bụla ọzọ, nke na-eme ka ife soldering ọzọ siri ike zuru ezu izute ịgbado ọkụ chọrọ nke elu-edu sekit mbadamba;

(2) Ọnụ ego ọrụ dị elu.

N'ime ngwa bara uru nke ịgbazinye ebili mmiri ọdịnala, ịgbasa efere dum na-efe efe nke flux na ọgbọ tin slag na-eweta ụgwọ ọrụ dị elu. Karịsịa mgbe ịgbado ọkụ na-enweghị ndu, n'ihi na ọnụ ahịa nke enweghị ndu karịrị okpukpu atọ karịa nke ọrịre, mmụba nke ụgwọ ọrụ nke tin slag kpatara bụ ihe ijuanya. Tụkwasị na nke ahụ, onye na-emepụta ihe na-enweghị isi na-aga n'ihu na-agbaze ọla kọpa na pad ahụ, na ihe mejupụtara nke ihe na-ere ahịa na tin cylinder ga-agbanwe ka oge na-aga, nke na-achọ mgbakwunye mgbe niile nke tin dị ọcha na ọlaọcha dị oke ọnụ iji dozie;

(3) nsogbu nlekọta na mmezi.

Mgbanwe nke fọdụrụ na mmepụta ahụ ga-anọgide na usoro nnyefe nke ịkwanye mmiri, na tin slag emepụtara chọrọ ka ewepụ ya mgbe niile, nke na-ewetara onye ọrụ na-arụ ọrụ mgbagwoju anya na ịrụ ọrụ; N'ihi ihe ndị dị otú ahụ, a na-ahọrọ ịgbanye ebili mmiri.

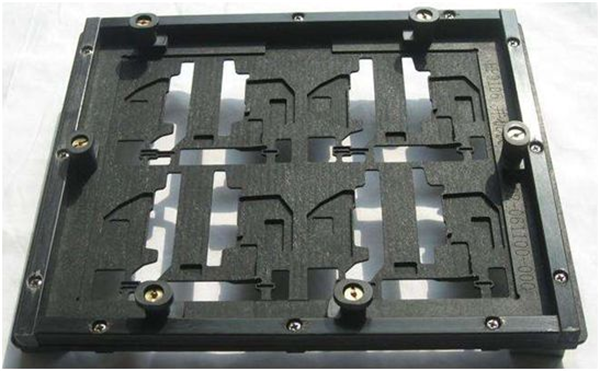

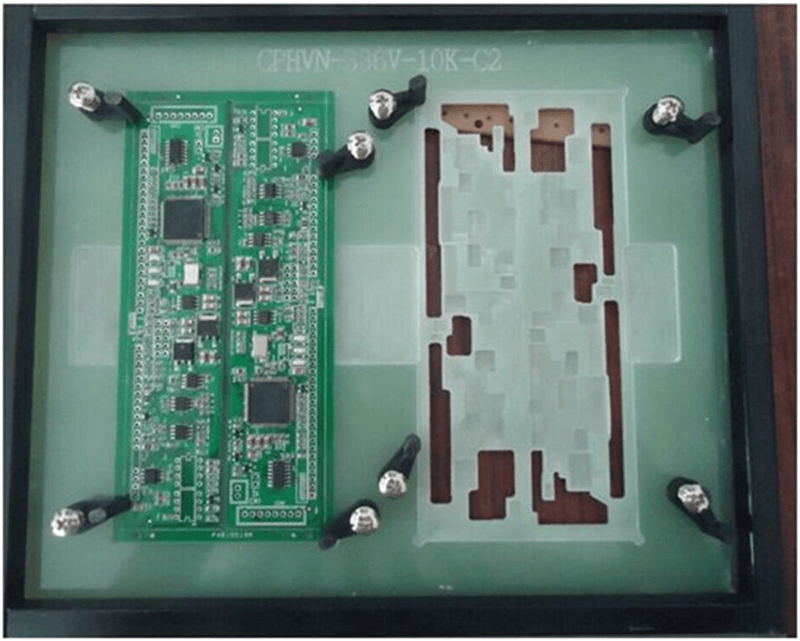

Ihe a na-akpọ PCBA selective wave soldering ka na-eji ọkụ agba agba agba mbụ, ma ihe dị iche bụ na a ga-etinye bọọdụ ahụ n'ime ihe a na-ebu ọkụ, nke bụ ihe anyị na-ekwukarị banyere ọkụ ọkụ, dị ka egosiri na foto dị n'okpuru ebe a.

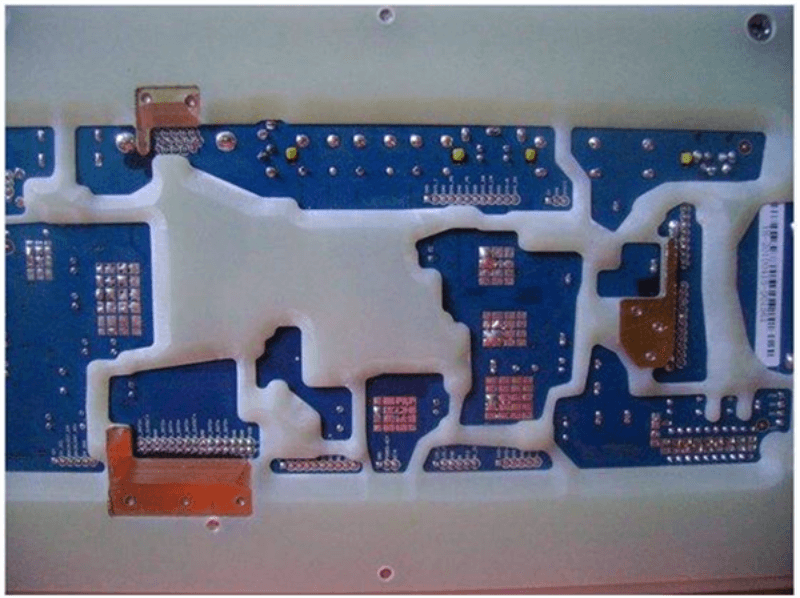

A na-ekpughere akụkụ ndị na-achọ ịgbanye ebili mmiri na tin ahụ, a na-echekwa akụkụ ndị ọzọ na mkpuchi ụgbọ ala, dị ka egosiri n'okpuru. Nke a dị ka ịtinye ihe na-awụ akpata oyi n'ahụ n'ime ọdọ mmiri, ebe mmiri ndụ kpuchiri ekpuchi agaghị enweta mmiri, ma dochie ya na stovu tin, ebe ụgbọala kpuchiri ya agaghị enweta tin, na nsogbu agaghị enwekwa ịgbaze agbaze ma ọ bụ akụkụ dara ada.

"Site na oghere reflow Usoro ịgbado ọkụ"

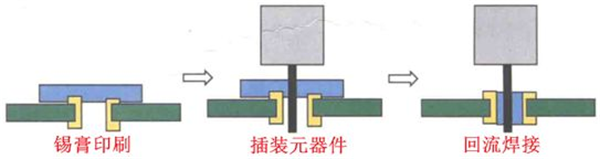

Site-oghere reflow ịgbado ọkụ bụ a reflow ịgbado ọkụ usoro maka inserting components, bụ nke tumadi na-eji n'ime imewe nke elu mgbakọ efere nwere ole na ole plug-ins. Ihe bụ isi nke teknụzụ bụ usoro ngwa nke tapawa solder.

1. Usoro mmeghe

Dị ka ngwa usoro nke solder mado, site oghere reflow ịgbado ọkụ nwere ike kewaa atọ iche iche: anwụrụ ibipụta site oghere reflow ịgbado ọkụ usoro, solder mado obibi site oghere reflow ịgbado ọkụ usoro na kpụrụ tin mpempe akwụkwọ site oghere reflow ịgbado ọkụ usoro.

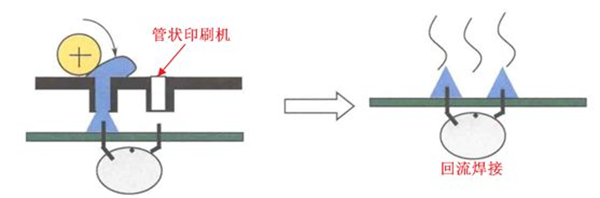

1) Tubular obibi akwụkwọ site oghere reflow ịgbado ọkụ usoro

Mbipụta tubular site na usoro ịgbado ọkụ na-agbado ọkụ bụ ngwa izizi nke site na oghere akụrụngwa reflow usoro ịgbado ọkụ, nke a na-ejikarị eme ihe n'ịrụ ụda TV agba. Ihe bụ isi nke usoro ahụ bụ ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe, a na-egosipụta usoro ahụ na foto dị n'okpuru.

2) Solder mado obibi site oghere reflow ịgbado ọkụ usoro

Solder mado obibi site na oghere reflow ịgbado ọkụ usoro bụ ugbu a kasị n'ọtụtụ ebe na-eji site oghere reflow ịgbado ọkụ usoro, tumadi eji maka gwakọtara PCBA nwere a obere ọnụ ọgụgụ nke plug-ins, usoro bụ n'ụzọ zuru ezu dakọtara na ot reflow ịgbado ọkụ usoro, ọ dịghị pụrụ iche usoro ngwá ọrụ a chọrọ, nanị ihe a chọrọ bụ na welded plug-in components ga-adabara site oghere reflow na-egosi na ọnụ ọgụgụ na-esonụ usoro.

3) Molding tin mpempe akwụkwọ site oghere reflow ịgbado ọkụ usoro

A na-ejikarị mpempe akwụkwọ agbado agbado site na oghere reflow ịgbado ọkụ maka ọtụtụ njikọ pin, solder abụghị solder mado kama mpempe akwụkwọ a kpụrụ akpụ, n'ozuzu site na onye nrụpụta njikọ agbakwunyere ozugbo, enwere ike ikpo ọkụ naanị.

Site oghere reflow imewe chọrọ

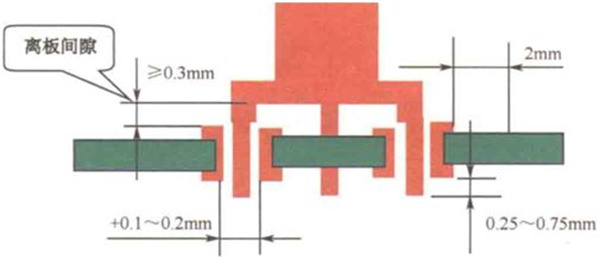

1.PCB imewe chọrọ

(1) Kwesịrị ekwesị maka ọkpụrụkpụ PCB na-erughị ma ọ bụ hà nhata na bọọdụ 1.6mm.

(2) Opekempe obosara nke mpe mpe akwa bụ 0.25mm, na tapawa solder a wụrụ awụ ka a “dọtara” otu ugboro, a naghị emepụta bead tin.

(3) Ihe dịpụrụ adịpụ nke bọọdụ (Nkwụsịtụ) kwesịrị ịdị karịa 0.3mm

(4) Ogologo kwesịrị ekwesị nke ndu nke na-esi na pad ahụ pụta bụ 0.25 ~ 0.75mm.

(5) Opekempe anya n'etiti ezigbo oghere dị ka 0603 na pad bụ 2mm.

(6) Enwere ike ịgbasa oghere kachasị nke nchara nchara site na 1.5mm.

(7) The oghere bụ ụzọ dayameta gbakwunyere 0.1 ~ 0.2mm. Dị ka e gosiri na foto na-esonụ.

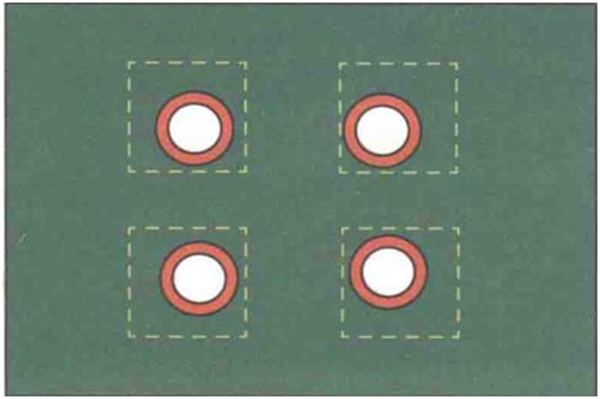

"Echọrọ imeghe windo ntupu ígwè"

N'ozuzu, iji nweta 50% ndochi oghere, a ghaghị ịgbasa windo nchara ígwè ahụ, a ga-ekpebi ọnụ ọgụgụ dị iche iche nke mgbasawanye mpụga dị ka PCB ọkpụrụkpụ, ọkpụkpụ nke nchara ígwè, ọdịiche dị n'etiti oghere na ụzọ na ihe ndị ọzọ.

N'ozuzu, ọ bụrụhaala na mgbasawanye adịghị agafe 2mm, a ga-adọghachi azụ azụ ma jupụta n'ime oghere ahụ. Ekwesiri ighota na enweghi ike ichikota mgbasawanye nke ozo site na ngwugwu ihe eji eme ihe, ma obu ga-ezere ngwungwu nke ihe eji eme ihe, ma mebe tin bead n'otu akụkụ, dika egosiri na onu ogugu ndia.

"Okwu mmalite nke Usoro Mgbakọ nke PCBA"

1) Ịkwado otu akụkụ

A na-egosi nrịbama usoro ahụ na foto dị n'okpuru

2) Ntinye otu akụkụ

E gosipụtara usoro a na-aga na foto 5 n'okpuru

The akpụ nke ngwaọrụ atụdo na ife soldering bụ otu n'ime ndị kasị nta ịrụ ọrụ nke ọma akụkụ nke mmepụta usoro, nke kwekọrọ ekwekọ na-eweta ihe ize ndụ nke electrostatic mmebi na ogologo oge nnyefe, na-abawanye ohere nke njehie.

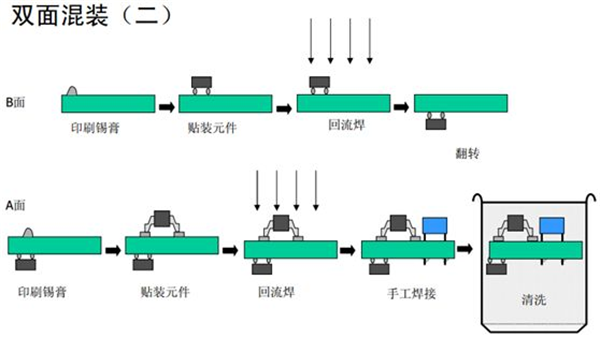

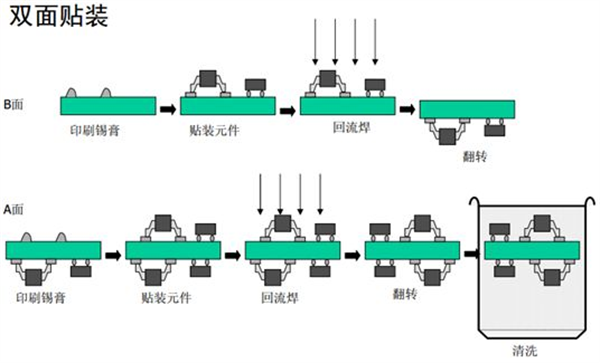

3) Nkwanye akụkụ abụọ

A na-egosi nrịbama usoro ahụ na foto dị n'okpuru

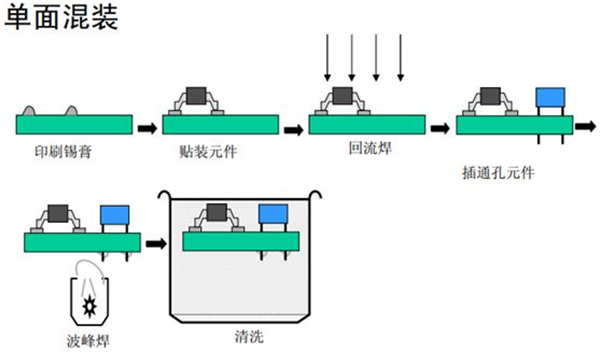

4) Otu akụkụ agwakọtara

A na-egosi nrịbama usoro ahụ na foto dị n'okpuru

Ọ bụrụ na ihe mejupụtara oghere dị ole na ole, enwere ike iji ịgbado ọkụ na ịgbado ọkụ n'aka.

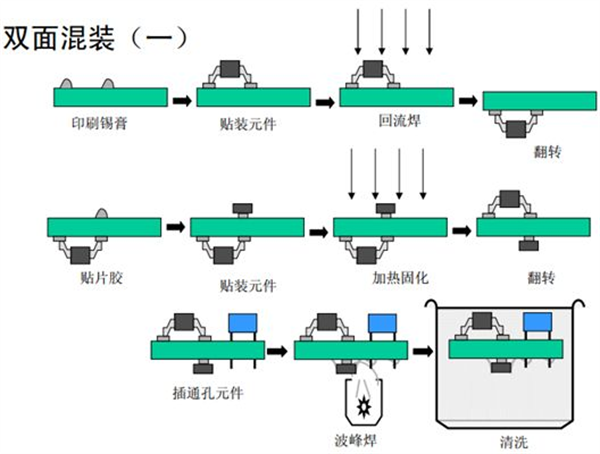

5) Ngwakọta akụkụ abụọ

A na-egosi nrịbama usoro ahụ na foto dị n'okpuru

Ọ bụrụ na enwere ọtụtụ ngwaọrụ SMD nwere akụkụ abụọ yana ihe ụfọdụ TTHT ole na ole, ngwaọrụ nkwụnye ahụ nwere ike ibugharị ma ọ bụ ịgbado ọkụ n'aka. E gosipụtara eserese usoro eruba n'okpuru.